Yaw Solutions

One of the most prevalent problems found across all Wind Turbine platforms happens in the yaw system design components. Further, from a point of view of the neighborhood community, noise emitting from the troublesome Yaw system (commonly referred to as "fog-horning") is a deterrent to both community relations and to new development. This article will review several of the components that are known to be troublesome from the design, repair, and obsolescent issues.

The turbine computer algorithm controlling the positioning into the wind (or out) initiates yawing dozens of times per hour. The nacelle-mounted electrical gear Yaw motors engage simultaneously, forcing the nacelle left or right, then disengage upon signal. The platform rotates on a steel disk fixed to the tower; the bearing is a simple set of friction discs or pads placed between the nacelle and the steel ring surfaces, acting as a movement deterrent and brake.

The most common turbine yaw systems use components that provide a basic slip-type deterrent pad and/or a clamp-brake design to control the movement of the turbine yaw. Most yaw motors have an integrated electrical brake.

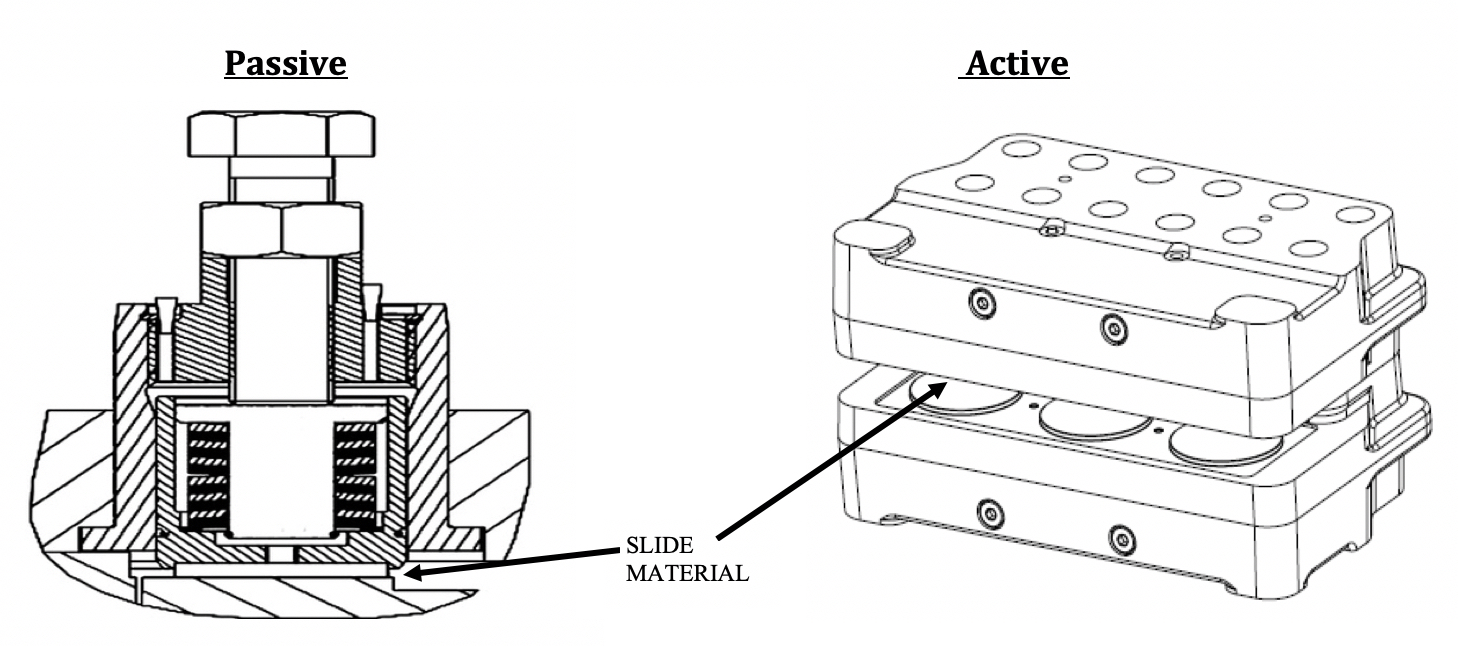

Two Yaw-slip deterrent typical types:

The most popular slide system is the passive. It includes a system of skid-disks, or pucks, in conjunction with a brass piston. Springs are housed internal to the piston, creating a defined but adjustable pressure downward to the steel that limits Nacelle movement caused by side-winds. Service technicians must regularly monitor the disc thickness and adjust the force onto the yaw-disc.

Turbines are located in all environments; local conditions including ambient air temperatures, moisture content, altitudes, and even simple maintenance practices, can become detrimental to reliable operation. The friction system components and associated electro-mechanical components are negatively affected by these conditions, causing operational problems in several areas.

SLIDE material

All Yaw systems are prone to vibration and noise (including the disturbing fog-horning noise), maintenance, and the skid-materials choice. Whether pad or puck, the various materials used to provide the slip-deterrent and yaw braking devices have undergone great research.

One model of turbine platform uses the passive design. This design requires multiple points of consistent downforce, exerted through spring pressure and delivered through placed brass pistons, which push onto and slide material referred to as slide pucks. There are 12 or 18 pistons per turbine, each requiring regular observation and maintenance. Experience with the piston-to-yaw ring interface has proven to have several inherent original equipment design issues, all needing solutions. Similar applications on other turbines use similar methods of implementation.

SLIDE-PUCK replacement

The frequency of replacement of the slide puck is determined by the user through experience, and is dependent on local conditions. During normal operation, the combination of puck and piston can also cause "fog horning" due to the sound of non-lubricated metal to metal contact. Turbines require either 12 or 18 pucks to operate.

Several OEM and 3rd party solutions have been offered with varied results. In 2016, testing began on a new composite alternative: a self-lubricating material surface called the "Super Puck" (in collaboration with several operators across diverse environmental locations). Super puck was subjected to long-term testing in various environments, under several corporate nationwide maintenance protocols. An extension of the Super Puck is the Super Piston. By using the same proprietary material, the one-piece Super Piston, integrated with the puck, replaces the brass piston; this offers extended life with the additional benefit of reducing the brass-piston generated noise and maintenance headaches.

YAW PISTON SPRING maintenance

Periodic maintenance or noisy operation may dictate a close inspection of the OEM puck, which requires extraction of the brass piston. Replacement with new springs should be an inherent part of the repair operation whenever new pad sets and holders or pistons are required. Excessive wear (as found on a worn-out brake pad) can expose the piston itself to contact directly with the steel yaw ring. This causes expansion of the brass outside of the sleeve hole onto the steel yaw ring surface. "Mushrooming" exposes the steel ring to resurfacing, which makes the extraction of the damaged piston extremely difficult and awkward; this situation may need several field-technician special techniques such as grinding and using hydraulic tools to remove the brass piston. To remove the damaged brass piston, a specialty tool system "Kit" has been developed with specifically designed hardware to ease the removal of a stuck/seized Brass piston.

Periodic maintenance or noisy operation may dictate a close inspection of the OEM puck, which requires extraction of the brass piston. Replacement with new springs should be an inherent part of the repair operation whenever new pad sets and holders or pistons are required. Excessive wear (as found on a worn-out brake pad) can expose the piston itself to contact directly with the steel yaw ring. This causes expansion of the brass outside of the sleeve hole onto the steel yaw ring surface. "Mushrooming" exposes the steel ring to resurfacing, which makes the extraction of the damaged piston extremely difficult and awkward; this situation may need several field-technician special techniques such as grinding and using hydraulic tools to remove the brass piston. To remove the damaged brass piston, a specialty tool system "Kit" has been developed with specifically designed hardware to ease the removal of a stuck/seized Brass piston.

YAW PLATE repair

If the tower fixed steel yaw ting has experienced damage, a number of repair methods can be applied, including a special puck to resurface and repair the damage without requiring removal from the tower.

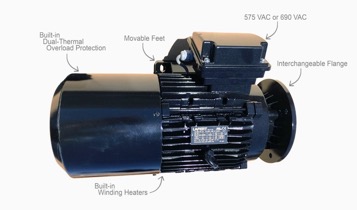

UNIVERSAL YAW MOTOR

Each turbine within a fleet has the unfortunate prospect of having been delivered with a slightly different yaw motor-gear design of the adjacent platform, despite a nearly identical electro-mechanical operation. These differences may include voltage, mechanical connection placement, thermistor counts, bearing and such. This problem can be solved with a new, universal yaw motor to meet the variable needs for the various OEM platforms.

Each turbine within a fleet has the unfortunate prospect of having been delivered with a slightly different yaw motor-gear design of the adjacent platform, despite a nearly identical electro-mechanical operation. These differences may include voltage, mechanical connection placement, thermistor counts, bearing and such. This problem can be solved with a new, universal yaw motor to meet the variable needs for the various OEM platforms.

With the proper tools, and service by knowledgeable and experienced technicians, keeping every turbine's yaw system operating smoothly is the solution to avoiding bigger problems down the line.

Bruce Hammett is President and CEO of WECS Renewables, and Denny McKissic is the National O&M Account manager. WECS is a distributor of components designed to extend the life of wind turbines. WECS works with vendors worldwide to provide factory replacement components, OEM alternatives, updates, and obsolescence alternatives.

WECS Renewables | wecsrenewables.com

Author: Bruce Hammett and Denny McKissic

.jpg?r=5287)