Battery Backup to Off-Grid - Navigating the transition

As net metering and other grid-tied subsidies dry up, more people are transitioning from battery backup to off-grid systems.

This article examines how to go off-grid, with an emphasis on reducing energy demands and selecting and sizing the right battery bank for a system.

Reduce energy demands

Battery backup systems only need to provide a few hours of electricity during power outages. Off-grid systems, however, must store enough energy to run an entire household every day, as well as hold ample reserves for cloudy or windless days.

Since every kWh requires additional solar or wind power, battery storage, and backup generation, it pays to start with improving efficiency and lowering electrical demand.

Simple steps include replacing inefficient appliances with Energy Star models, raising or lowering thermostat settings seasonally, and putting vampire loads on switchable power strips.

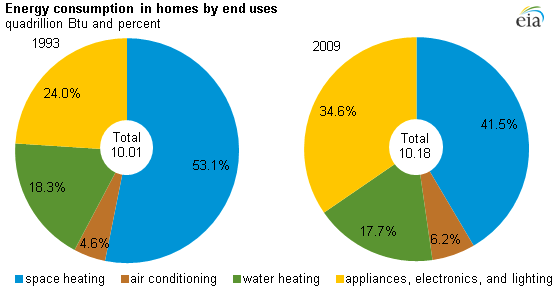

Because almost half of household energy consumption goes to space heating and air conditioning, upgrading attic and wall insulation can slash heating and cooling demands.

In addition, mechanical systems like compressor-less Variable Refrigerant Flow HVAC technology can cut HVAC energy usage by ~90%, without sacrificing comfort. Other options are inexpensive whole-house fans and simple ventilation systems that draw in cool night time air and expel heat. (See "Living the Dream of Net-Zero Energy & Storage - March/April 2015.)

Calculate electrical load

Calculate electrical load

After reducing electricity demands, review the past year's utility bills to identify a baseline of power needs.

Inexpensive devices can reveal vampire loads and provide accurate power monitoring for individual appliances. This data can then be applied to the basic calculation for power needs: Watts = amps x volts.

For instance, if you need 1,000 Watt hours (1 kWh) a day, and have a 12-volt battery bank, you'll need 84 amp-hours of storage.

Add additional storage capacity for worst-case scenarios

Off-grid systems aren't connected to the power grid. Batteries require additional capacity to store solar or wind energy for extended periods, without over-discharging batteries.

Undersized solar panels and battery banks make it difficult to use large appliances and slash battery life through over-discharge. If storage reserves dwindle, off-grid homeowners could be left in the dark.

Important considerations for additional capacity include: number of days of autonomy (no sun); seasonal variations in wind generation; hot streaks that increase A/C use; decreased sun-hours during winter; and foggy and cloudy days that reduce solar output.

Maintain a safe depth of discharge (DoD)

Every off-grid household needs reserve power for heavy loads and cloudy days with limited solar charging.

Some battery technologies tout 80% or 100% DoD. They even compare their affordability using unrealistic and unsafe assumptions, such as needing half as much capacity as other technologies. However, when any battery is discharged 80% or more, it has almost no reserve capacity left to run high-energy appliances. It certainly won't deliver enough electricity to power common household appliances during low-solar days.

Plan on a maximum of 50% DoD. A good rule of thumb is to double the calculated ampere-hours needed.

Select the right batteries

Select the right batteries

Lead-acid and lithium-ion (Li-ion) are the most common battery types, but there is no one-size-fits-all battery technology. It's important to consider technology type, preferred voltage, ambient temperature, maintenance requirements, recyclability, and cost.

Li-ion batteries offer higher energy density and reduced weight, and, like some lead-acid batteries, don't require regular maintenance. However, Li-ion batteries have a shorter lifespan and can cost up to 10X as much for the same capacity as their lead-acid counterparts. They also require battery management systems (BMS) to protect against cell damage and overheating (which can start fires). Recyclability varies from 0% to 60%, with fewer than 20% of Li-ion batteries partially down cycled.

Lead-acid batteries are the most-used because they've been proven for over 100 years. They're also economical, at 50% to 90% cheaper than other technologies. According to the US Environmental Protection Agency (EPA), lead-acid batteries are 99% recyclable and 99% recycled - the highest recovery percentage of any product in the USA.

The most common battery options are flooded lead-acid, which require periodic water service and other preventative maintenance throughout battery life, and sealed valve-regulated lead-acid (VRLA), which are maintenance free but more expensive than flooded batteries.

Look for key features for longer battery life

- Heavy, gravity-cast plates with more active lead allow for more chemical reactions and longer life;

- Previously recycled, 100% recyclable lead improves sustainability;

- Computerized lead oxide mixing, plate curing, and formation charging maximize performance and consistency;

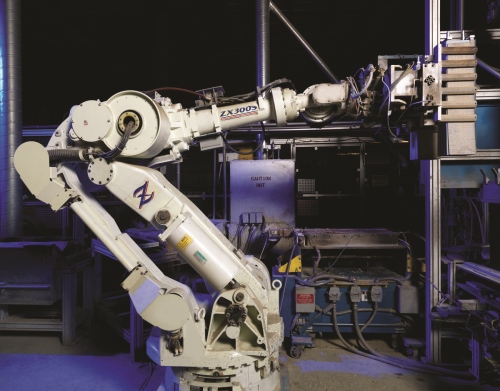

- Robotic cast-on strap (COS) welding allows for over 4,000 adjustments versus 40 for manual welding, improving lifespan and reliability;

- Automated vision systems eliminate common human errors and ensure quality.

Extend lifespan with proper storage

Batteries last longest in moderate temperatures (ideally, 77 °F). Each 18 °F temperature increase reduces the number of cycles available by half. Lower temperatures increase lifespan but reduce available capacity.

Avoid putting batteries in insulated coolers and old refrigerators, which trap heat and spike battery temperatures.

House batteries in well-ventilated locations or standalone utility structures.

Make maintenance easy

Maintenance is crucial for lifespan and performance. Typical maintenance includes adding distilled water, checking and cleaning connections, and effective battery charge control setup and operation. Follow manufacturer recommendations and schedule periodic maintenance on the calendar.

By following the approach in this article, navigating the transition from battery backup to off-grid can be fast and easy - and electrical bills will be a thing of the past.

John Connell is the vice president of Crown Battery's SLI Products Group. Crown Battery manufactures all its advanced technology, lead-acid batteries at its ISO-9001:2008-certified plant in Fremont, Ohio.

Crown Battery | www.crownbattery.com

For more information, see:

How to select the right AGM battery

Will It Recycle?

Volume: 2016 November/December