Hidden Costs of Inaccurate State of Charge

The anxiety and, let’s be honest, fear when your phone’s battery hits 20 percent charge is palpable. Perhaps it’s because we have all experienced that moment when a phone went from 20 percent to 0 percent in the blink of an eye. Conversely, many of us also know the joy of when your phone’s last 1 percent magically lasts way, way longer than expected.

This happens because the percent charge, the State of Charge (SoC), is not a measured value. Instead, it is a complicated calculation done by a very small computer. Each energy storage system contains thousands of modules, with each containing a Battery Management System (BMS). The BMS is a critical piece of all energy storage systems. It regulates the behavior of the battery system, preventing it from operating with voltage, temperature, and current values outside safe ranges.

The problem is that most BMSs can only provide simple computations, and lack the processing power for more complex calculations. This hampers a storage system’s ability to perform accurate SoC calculations.

Calculating SoC

SoC calculations have two primary components: the battery’s chemistry, and its open circuit voltage (OCV) estimate.

Battery chemistry

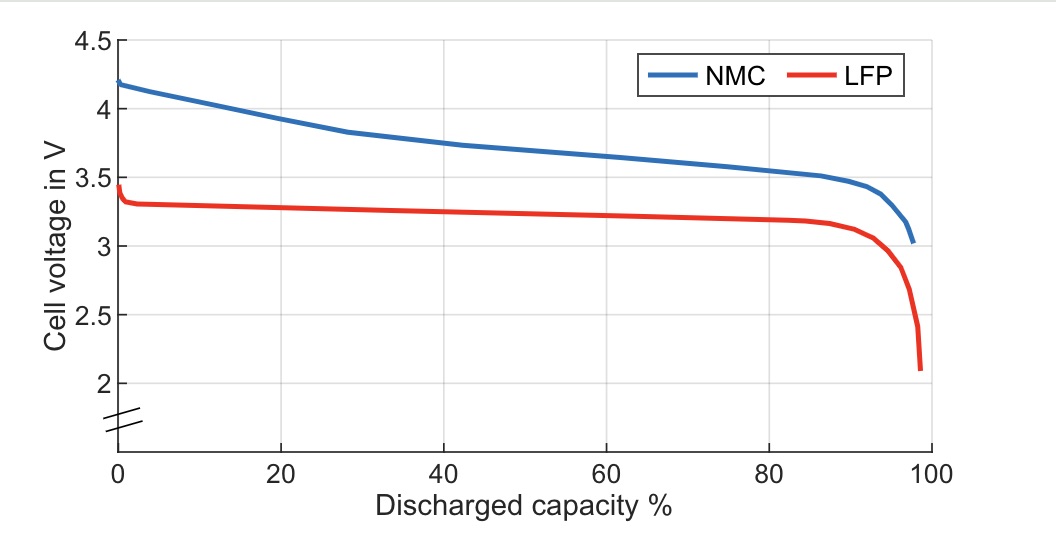

Each battery chemistry has its own unique OCV curve fingerprint, even within specific lithium-ion battery types. For example, the OCV curve of a Nickel Manganese Cobalt (NMC) battery has a different profile than a Lithium Iron Phosphate (LFP) battery. (Figure 1)

Open circuit voltage estimate

The OCV is the battery’s voltage when no external current is flowing. All chemical reactions inside the battery are relaxed, meaning that there is no voltage drop due to the battery's internal resistance anymore. However, we can only accurately measure the OCV in moments when the battery has completely stopped or otherwise removed the load.

But there is a problem. As you can see, the overall flatness of the OCV curve complicates matters — especially in the case of LFP batteries. There is no significant voltage difference between the OCV of a full versus empty battery, and there is very minimal change from 90 percent to 20 percent. Getting correct OCV measurements can be extremely difficult as many systems operate continuously, presenting very few relaxed voltage measurement opportunities. Thus, the OCV is usually estimated, and a small error in OCV estimation can easily result in a SoC error of 5 percent to 15 percent.

What are the real-world implications?

Today, many asset owners operate their energy storage system with a conservative SoC cushion rather than pushing their batteries to near full discharge. Typically, operators maintain an error margin of up to 10 percent, which will prematurely slow the discharge of the battery to avoid deep discharge. This cushion allows for slack in case of an SoC error, but it also prevents the battery from being used to its capacity.

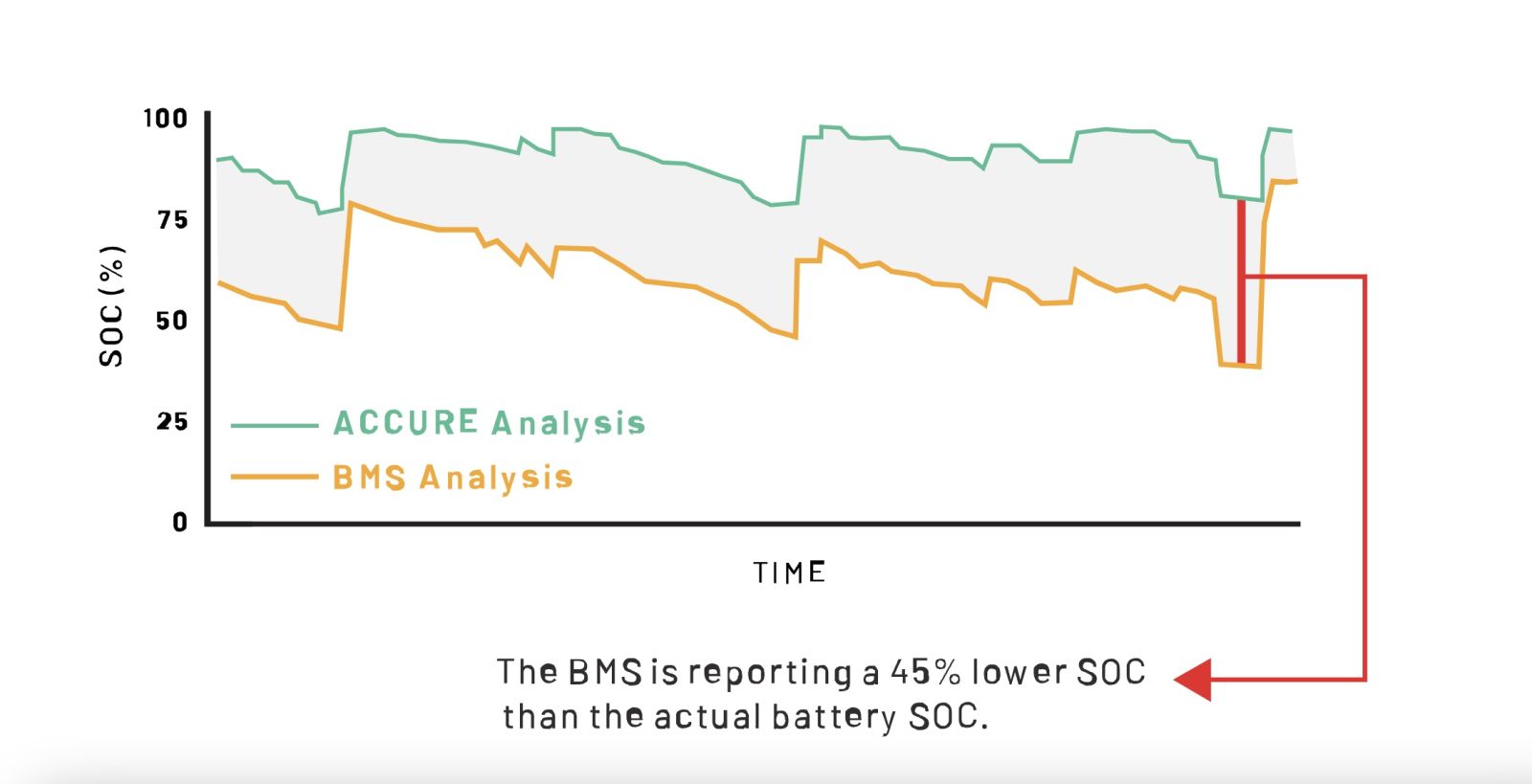

Top of mind for many large-scale storage operators is the understanding that high SoC error margins mean missed revenue. We consistently see SoC errors of up to 15 percent, and have reviewed data from sites with up to 45 percent errors (Figure 2).

Inaccurate State of Charge (SoC) estimates can lead to two key financial risks:

- Trading errors: Selling too much or too little energy due to incorrect SoC reduces efficiency and revenue.

- Penalties: Failing to meet market requirements can result in fines or even market exclusion.

In 2023, energy storage assets in ERCOT earned an average revenue of $196k per MW. Therefore, a system with a 15 percent SoC error loses nearly $30k per MW annually. Even if the system had just a 5 percent SoC error, the asset owner would lose nearly $10k per MW.

This deeply cuts into the payback periods and profits of storage projects.

How do we improve SoC accuracy? The answer is data.

While a BMS is limited by its computational power, it does have a superpower — it records data. The BMS is constantly monitoring and storing temperature, voltage, and current data. With this data, a more powerful cloud-based system can perform computationally intense physics-based modeling to calculate a precise SoC for the storage system.

Cloud-based battery management system analytics leverage artificial intelligence and machine learning to significantly enhance the accuracy of SOC estimation. This improvement goes beyond operational efficiency — directly boosting storage systems' revenue potential. Additionally, advanced software solutions factor in battery aging, ensuring more reliable performance over time. Implementing these solutions primarily involves server costs and labor, but they offer the advantage of rapid, cost-effective scalability across numerous systems.

The asset owner can integrate the more precise SoC into a trading platform to make better informed decisions about when to buy and sell electricity. With this information, the trading platform can adjust its bids to the maximum available energy, thus allowing for increased trade and revenue.

By improving the accuracy of SoC calculations, we can push batteries further. Correcting SoC inaccuracies allows you to reduce the error margins, letting you sweat the battery for more profit, increasing bankability, and helping make the world just a little bit more sustainable.

Elizabeth Oliphant is a Solution Engineer Manager, and Jasper Seitz-McIntyre is a Solution Engineer at ACCURE Battery Intelligence, which makes batteries safer, more reliable, and sustainable using data analytics.

ACCURE Battery Intelligence | www.accure.net

Author: Elizabeth Oliphant and Jasper Seitz-McIntyre

Volume: 2025 January/February