IDTechEx Explores the Role of Cathode Innovation for Greener Batteries

Improving the performance and reducing the cost of Li-ion batteries have been primary concerns for the Li-ion battery industry over the past 10-15 years. The environmental and societal implications of Li-ion battery production and deployment have come under increasing scrutiny, along with concerns regarding supply chain concentration. This is particularly important given the rate of growth in Li-ion demand - IDTechEx forecasts global Li-ion battery demand to grow at a CAGR of 16.7% from 2023-2034.

In Europe, for instance, the forthcoming battery passport will enforce requirements on carbon intensity and mandate labeling regarding the amount of critical materials contained within batteries, such as lithium, cobalt, and nickel, and their origin. This regulation underscores the necessity for the industry to adopt more sustainable practices.

Cathode material innovations

To date, significant advancements in Li-ion battery technology have centered around optimizing cathode materials that have been commercial for over a decade, namely NMC (Nickel Manganese Cobalt Oxide) and NCA (Nickel Cobalt Aluminium Oxide). These cathodes have been a particular area of interest as they are the source of cobalt within Li-ion batteries while also being a key determinant of cell cost. During periods of high material prices, such as in 2022, IDTechEx estimates that the cost of the cathode could contribute to over 60% of the cost of manufacturing an NMC cell. Historically, the use of cobalt has been particularly scrutinized due to its problematic sourcing from the DRC, but the production impact of other materials, including lithium, nickel, as well as graphite anodes, also warrants close consideration.

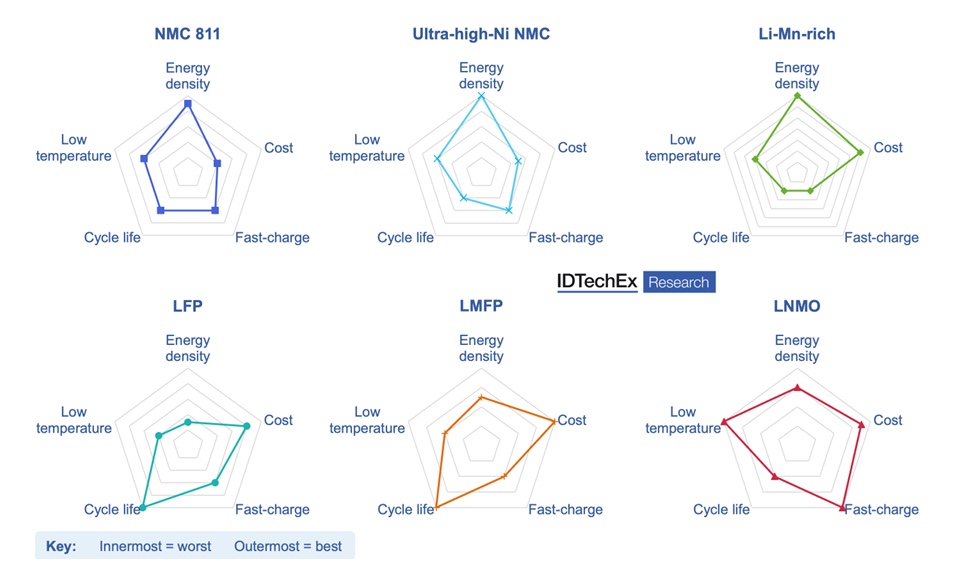

Cathode comparisons. Source: IDTechEx

Historically, there has been a steady reduction in the cobalt content of NMC and NCA-type cathodes, accompanied by an increase in nickel content, which also enhances energy density. Companies are now commercializing ultra-high nickel layered oxides, with nickel contents approaching and even surpassing 90%, enabled through changes to particle structure and design, as well as coatings and electrolyte additives. Optimizing electrolyte, cell, and battery pack design has also been crucial in maximizing the performance of more affordable LFP batteries. LMFP (Lithium Manganese Iron Phosphate) represents the next evolution in LFP development, incorporating manganese into the cathode to achieve a higher average voltage, which can boost energy density by 10-20%. Subsequently, LMFP batteries can reduce the total amount of material needed per kWh of battery, an important lever for minimizing the impact of battery production. Additionally, Li-Mn-rich, high voltage LNMO (Lithium Nickel Manganese Oxide) and the recent introduction of DRX (Disordered Rocksalt) cathodes offer alternatives that balance the high energy density of high-nickel layered oxides with the low cost of LFP. These advancements can also minimize the reliance on cobalt and nickel, addressing some of the environmental concerns associated with these materials.

Innovations in cathode manufacturing

Beyond material innovation, new cathode manufacturing and synthesis methods are in the early stages of being commercialized. These approaches promise faster production times, lower water consumption, and lower energy consumption, with the added benefit of enabling the use of lower-cost precursors. They can also eliminate the sulfate waste streams that are becoming increasingly scrutinized, especially in regions where strict environmental permitting requirements exist.

While alternative synthesis methods have garnered interest, conventional methods using co-precipitation and solid-state synthesis still dominate global cathode production. However, several companies, primarily based in North America, are leading a shift towards alternative cathode production practices. Examples include 6K Energy, Nano One Materials, and Sylvatex. Direct recycling and other battery recycling routes offer a separate route to lower cathode production costs with lower associated environmental impacts.

Outlook

While cathode material advancements alone will not herald the next revolutionary battery technology, they are crucial for optimizing the performance, cost, and environmental footprint of Li-ion batteries. Continued innovation in both materials and manufacturing processes will be essential for the industry to meet growing demands while addressing environmental concerns.

For more information on Li-ion cathode innovation and the battery market, please see the IDTechEx report www.IDTechEx.com/AdvLithium. Downloadable sample pages are available for this report.

IDTechEx | https://www.idtechex.com/