Supercharging Battery Energy Storage Infrastructure

The global power industry is changing rapidly. First and foremost, utilities are seeing increased public pressure from consumers to source their energy via more renewable methods. Yet business and industry are also exerting more pressure for change as they manage their scope 2 and 3 emissions to meet increasingly ambitious net zero goals.

The rise in variable generation, such as solar and wind, has heightened the need for utility-scale battery energy storage to help mitigate the effects of intermittent power production and maintain grid stability. Battery storage facilities can act as a load by absorbing excess generation. They can also smooth out system operation by supplying power boosts to support voltage, frequency, and peak demand needs.

Owners and operators of these assets are often perfectly positioned to take advantage of fluctuating energy markets, but only when their operations empower them to be nimble. Such operations require the comprehensive visibility and easy control provided by fit-for-purpose green energy management solutions, with integrated asset management and supervisory control and data acquisition (SCADA) software.

Increased complexity of managing I/O

One of the primary factors that gives utility operators pause as they pursue battery storage projects is the perceived complexity of the shift from a very operational technology (OT)-centered infrastructure, to a more information technology (IT)-focused one. While a traditional power generation automation project had dozens of cabinets where engineers wired in transmitters and other field devices, renewable automation projects are more IT-based, with many datalink connections via Ethernet or fiber optics. I/O are often addressed as IP devices, and gather data using industry-standard protocols.

This shift from hard I/O to soft I/O typically results in a less tangible I/O base, resulting in hundreds or thousands of I/O points across the system. While more power capacity means more capability, it also means far more communication points.

The I/O generated by individual battery cells or modules is managed by an OEM battery management system (BMS), and DC to AC voltage conversion is handled by the power conversion system (PCS or inverter), typically provided by a different OEM. Depending on site configuration — a single unit representing a collection of similar battery modules, a plant consisting of multiple units, or units or plants connected to renewable generation like solar — the breadth of equipment-generated I/O that needs to be managed by operations could be overwhelming, which could result in inefficient support of daily energy storage site operations.

Moreover, with the intricacies of the modern supply chain, there is no guarantee that every piece of equipment will be sourced from the same manufacturer. Ultimately, a site could very easily end up with numerous BMS and PCS installations from a variety of OEMs — which escalates when more storage is added to a fleet — increasing operational complexity.

As operators try to manage their daily tasks (how many batteries are at full capacity, how many have faults or alarms, how many are in automatic versus manual control), they will need to be trained to operate and support multiple systems. This will require extra time and cost to navigate different interfaces for the same issues, while introducing delays to what are often time-critical tasks.

A single solution for unified control

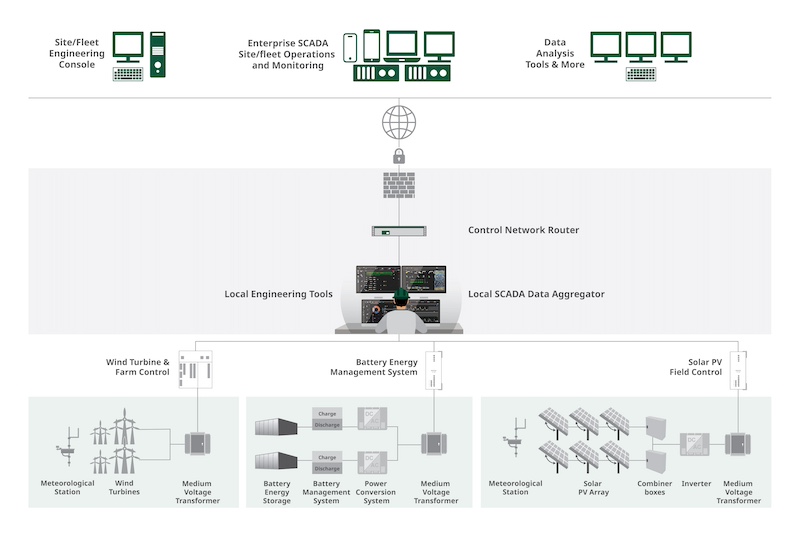

The organizations having the most success establishing, maintaining, and optimizing battery storage operations are bringing all their systems together into an integrated solution, with a single dashboard for a clear and comprehensive view of operations. These implementations rely on field-proven and fit-for-purpose green energy management solutions based on SCADA software created by automation suppliers with decades of experience in both the automation and energy industries (Figure 1).

Figure 1: Implementing an integrated, field-proven energy management system that seamlessly aggregates and moves data from the field to the enterprise provides a foundation for long-term safe, efficient, and profitable operations.

The best energy management systems aggregate all the battery storage I/O into a central point, and they use one intuitive dashboard to provide clear operational visibility and control of hundreds or thousands of devices and I/O. Plant staff have continuous access to aggregated data for efficient operation and troubleshooting of their battery systems from the same location, without jumping between operating environments.

Using built-for-purpose battery energy management solutions with SCADA software not only saves time by eliminating the need for operators to travel to one or multiple battery energy sites, it also helps enforce consistency and repeatability of operations. Operations and maintenance staff can be trained on one system and know that their skills will apply to every piece of equipment, regardless of OEM. They also gain access to broad, reliable, comprehensive customer support to help them navigate the complexities of aggregating a wide array of disparate systems.

When organizations select proven, experience-backed energy and asset management software, they are also more likely to be able to control additional assets (wind, solar, hydro, and even fossil-fuel sites) alongside their battery energy storage. This increased flexibility makes it easier to bring multiple critical systems together into a remote operations center, where the organization’s best and most experienced personnel can more efficiently manage a wider array of fleet-wide assets (Figure 2).

Figure 2: Providing a unified view of contextualized, real-time operational data with purpose-built asset management and SCADA software improves situational awareness, helping operators to isolate critical information more quickly and to make better, safer decisions.

A foundation for a greener future

Battery storage is a new frontier for many utilities venturing into the renewables sector; there are often many unknowns. While a wide variety of energy management and SCADA solutions for battery storage exist, the most effective solutions across the lifecycle of a company’s equipment will be those built from the ground up by an automation solutions provider with deep expertise in energy generation.

Not only will such solutions be easier to install, configure, manage, and maintain, they will also be designed with the capability for expanded operations, making it easier to use to efficiently monitor all the energy storage and generation assets the organization owns or may acquire. The full access to data, clear operational visibility, and intuitive control provided by an integrated green energy and asset management solution can be the foundation for decades of safe, efficient, and profitable operation.

Anthony LaMantia is senior engineer at Emerson, where he oversees implementation of renewable solution projects, and helps to lead the digital transformation of power industry customers. He is responsible for the successful execution of automation projects for renewable assets, with a focus on solar PV and battery energy storage. Anthony received a Bachelor of Science from the University of Pittsburgh in Applied Mathematics.

Anthony LaMantia is senior engineer at Emerson, where he oversees implementation of renewable solution projects, and helps to lead the digital transformation of power industry customers. He is responsible for the successful execution of automation projects for renewable assets, with a focus on solar PV and battery energy storage. Anthony received a Bachelor of Science from the University of Pittsburgh in Applied Mathematics.

Emerson | www.emerson.com

Author: Anthony LaMantia

Volume: 2024 May/June