Avoiding Costly Main Panel Upgrades

Around 20-30 percent of solar installations are impacted by main panel limitations. NEC’s 120% rule often necessitates expensive main panel upgrades, potentially costing $2,000 to $5,000 or more with labor, permitting, and additional electrical work. In some jurisdictions, panel upgrades aren't even an option.

120% Rule – to protect overloading busbars

The National Electric Code (NEC) 705.12(B)(2), or the “120% rule,” ensures safe solar power system operation by preventing overloads and electrical fires. It restricts the combined current from all power sources to 120 percent of the busbar rating, limiting the amount of solar which can be added to a system.

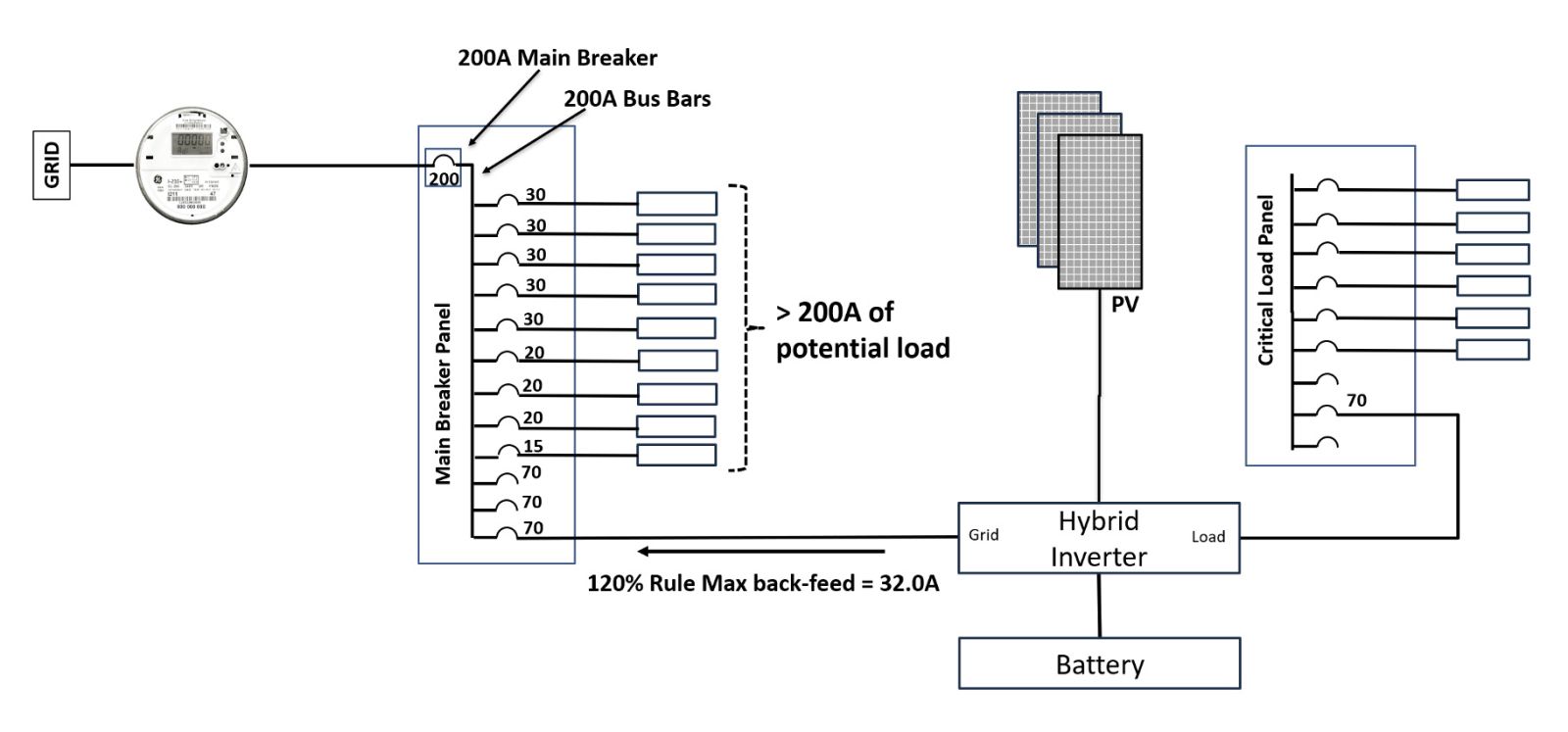

Figure 1: A typical 200A electrical panel with PV source (32A) to meet the NEC 705.12(B)(3)(2), a.k.a. the 120% rule

In the above illustration, a 200A main panel breaker and 200A busbar would be allowed to accommodate 240A of combined continuous inverter output rating and main breaker size (120 percent of 200) under the 120% rule. This allows for a 40A PV source back-fed breaker or 32A (40/1.25) continuous PV source, meaning a typical 200A panel cannot support more than 32A of continuous PV source. However, many modern residential systems exceed this due to increased energy demands from EVs, larger solar systems, and the need to maximize solar with batteries. So, how can we add more solar to the existing breaker panels?

Meeting 120% rule is Complex and Expensive

Most installations use one or more of the following options to meet the 120% rule:

- Upgrade the main service panel with an increased busbar rating

- Downsizing the main breaker

- Derate the PV inverter

- Supply side (line side) tap or feeder tap

Options 1 and 4 increase solar capacity but come with high installation, labor, and material costs. Options 2 and 3 downsize the system to meet the limit. None of these four options is ideal for homeowners wanting to add more solar.

- Downgrading the main service breaker is not always possible as your AHJ may ask you to redo the house's load calculations according to NEC 220. Reducing your main breaker size would imply that you are reducing the loads from the original service entrance calculations while at the same time proposing to increase the loads with the powerful battery charger that is part of the new solar inverter.

- There is a high chance that customer will back off from his solar contract if faced with proposal to upgrade main panel, as the added labor and cost is upwards of $5,000 for the new panel.

- Installations in California may not be possible for supply-side tap because in California both meter and main panel are in a single box, called “meter main panel”, and you can’t access supply side to tap the inverters.

- You are hobbling your inverter by derating them to meet the 32A limitation on the 200A.

PCS (Power Control System) is a new way to surpass 120% rule

Fortunately, the 2020 NEC introduced a new rule to surpass the 120 percent limit. NEC 705.13 allows Power Control Systems (PCS) to provide overcurrent protection for the busbar instead of relying solely on breakers, enabling larger PV systems to connect to the busbar as long as the PCS limits the back-fed current. In NEC 2023, PCS is redefined as Energy Management Systems (EMS) with the same function of limiting busbar current.

How does a PCS help avoid main panel upgrade?

The PCS actively monitors and controls the current on the busbars without violating the 120% rule or incurring expensive panel upgrades. PCS uses its internal and external CTs to measure the grid current and removes the inverter contribution to the busbar current if it detects a busbar overload.

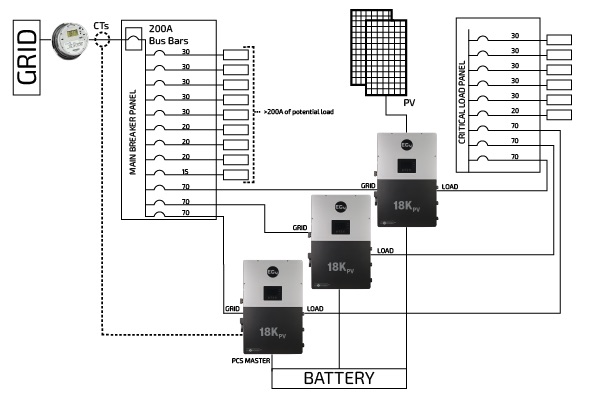

Figure 2: PCS controlled 200A breaker panel with 150A PV source, without needing to upgrade the main panel

Final Note: PCS is the way to go!!

PCS is a significant innovation in residential solar, providing a smarter, more flexible approach to managing solar energy integration. It enhances safety, compliance, and efficiency while reducing costs, making solar more accessible and financially attractive for homeowners. By controlling power flow, PCS addresses many barriers to solar adoption, making it a cornerstone for the future of residential solar.

Naveen Tera, Director of Compliance Engineering at EG4, oversees the adherence of products to regulatory and industry standards. His expertise ensures that EG4’s solutions meet all necessary compliance requirements while maintaining high quality and safety. Naveen holds MSEE and Executive MBA degrees.

EG4 Electronics | eg4electronics.com

Author: Naveen Tera

Volume: 2024 November/December

.png?r=6187)