Capture Rays and Competitive Advantage

Digitalization is a critical strategy for competitiveness in the era of rapidly expanding solar generation.

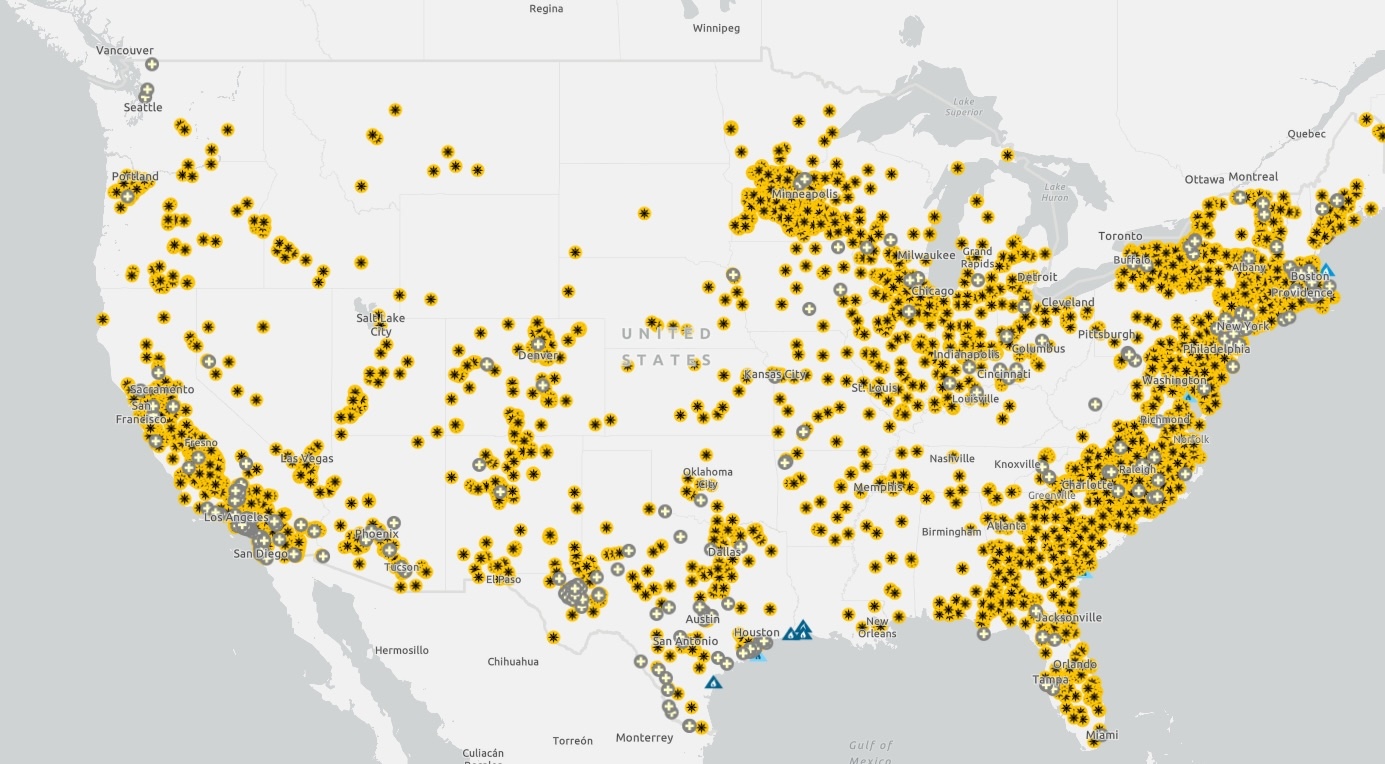

There can be little doubt that the power generation industry is changing at a pace the world has never seen. Much of this change is a result of the rise of renewables — solar energy in particular — that are rapidly expanding to meet a global demand for electrification, while reducing carbon emissions. As consumers add an increasing number of electronic devices to their daily lives, the automobile industry rapidly transitions to electric vehicles, and individuals and governments call for more sustainable solutions, the need for solar generation continues to grow (Figure 1).

Figure 1: To help meet the increasing demand for electrification and decarbonization, renewable energy, particularly solar and battery storage, is rapidly growing worldwide, including in North America. Source: U.S. Energy Information Administration (Nov./Dec. 2024)

Meeting those needs on a large scale means finding new ways to operate. The traditional utility model of individual power and distribution sites staffed with a deep bench of on-site expert personnel is changing. New methodologies favor a model of distributed energy resources that result in utilities and independent power producers managing expansive fleets of assets that span cities, states, and even countries. Efficiently and effectively managing those geographically dispersed assets is difficult. As a result, forward-thinking companies are evolving by digitalizing their operations, empowering their personnel to change complexity into opportunity.

Evolution requires new strategies

The earliest solar production was far less complex than today’s operations, as concentrated solar was more akin to traditional generation. Producers used solar collectors, instead of fossil fuels, to produce steam that turned turbines. Concentrated solar sites could produce substantial energy to contribute to the grid; because a turbine was still at the heart of operation, they had inertia and excitation to support grid stability.

In parallel, early solar PV farms were nearly analog operations. Typically, producers would put as many megawatts (MW) on the grid as possible at a fixed voltage schedule and power factor, because the increase in energy was not significant to grid support compared to fossil-fuel generation.

Today, however, as the cost of PV solar has gone down, the number, size, and scope of solar farms has increased dramatically. In some states, solar can account for up to 30 percent of generation, which means solar energy operators need dynamic control strategies — including curtailment, power system stabilization, variability management, and more — to prevent brownouts and surges. To address these and other issues, today’s teams need purpose-built software and algorithm-based digital control to respond quickly to grid needs.

Ready to report

More complex control is not the only responsibility of modern solar operators. As suppliers build and acquire assets, creating bigger portfolios, regulatory agencies like the North American Electric Reliability Corporation (NERC) are taking notice, and adjusting requirements for reporting accordingly. Perhaps the best example is the anticipated requirements change for NERC’s Generating Availability Data System (GADS) reporting. In 2024, only solar plants with a total installed capacity of 100 MW or more are required to submit GADS reports. However, on January 1, 2025, any solar plant with a total installed capacity of 20 MW or more will be included in the requirement as well. While that is a big adjustment, there is no assurance it will stop there in the future.

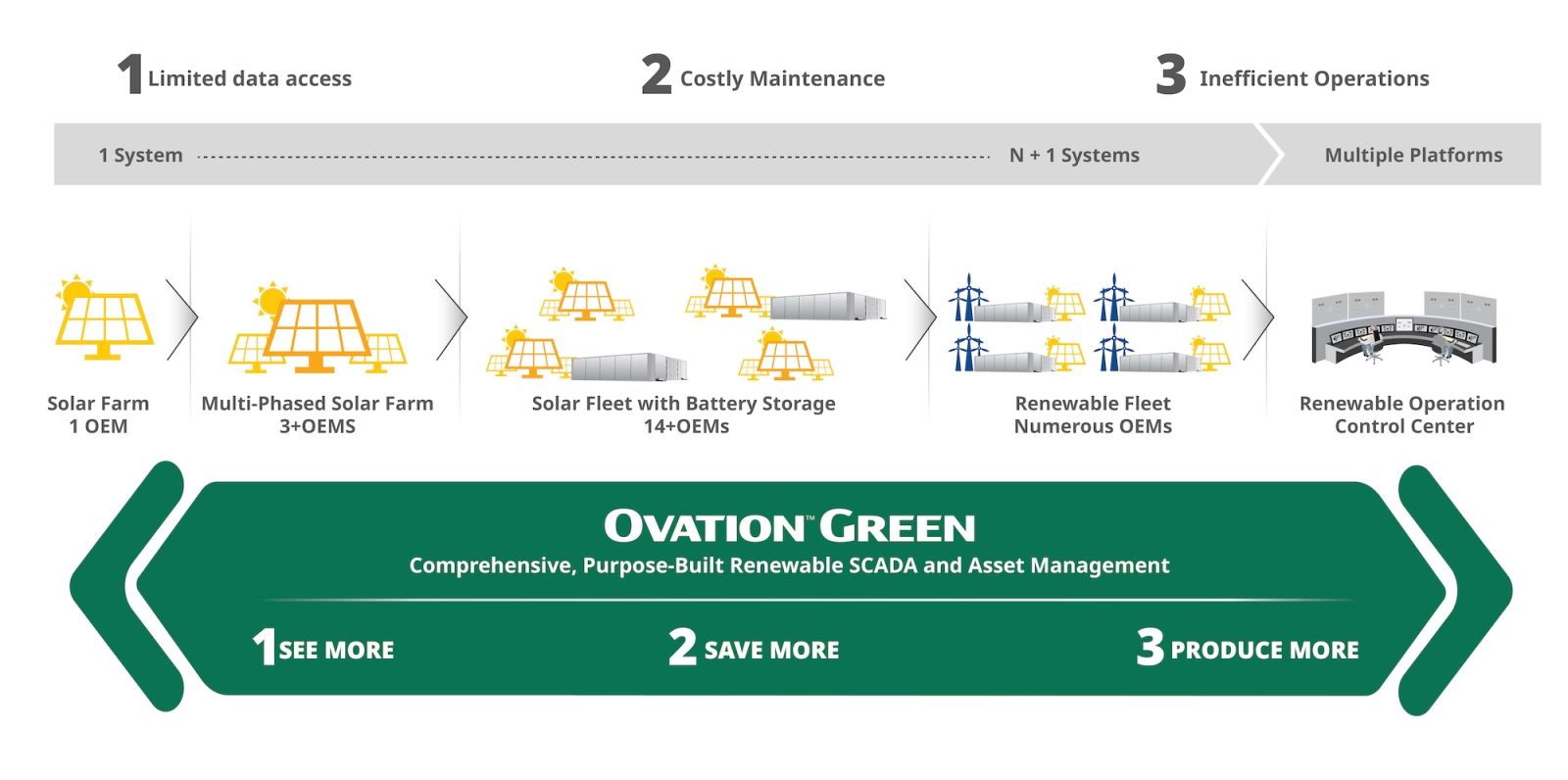

GADS reporting is not as simple for solar producers as it is for traditional power generation facilities. Where a large traditional utility might have 300 generating resources throughout the entire company, some solar farms may have dozens of central inverters, or even hundreds of string inverters at a single site, to incorporate into plant reports. Moreover, each traditional utility site likely has many personnel onsite 24x7, some of whom might even be specifically responsible for sending select data to corporate for NERC reporting. In contrast, most large solar farms are not staffed, so the vast amount of support data for NERC reporting must be collected and classified by personnel offsite. The amount of work increases significantly as more solar farms are added to a portfolio (Figure 2).

Figure 2: Renewable portfolio growth comes with ever-increasing complexity. Applying a single, unified asset management and SCADA solution decreases complexity, enabling owners and operators to see more data, save on maintenance costs, and produce more energy.

In such a situation, digitalization is essential for efficient, effective operation. Remote teams need an automated system to collect, classify, and automatically generate GADS reporting information. Instead of requiring an operator to collect data from multiple assets and manually generate reports, SCADA systems with built-in GADS reporting automatically associate NERC codes to classify events as they occur, making it easy to pull the events into reports.

For example, if a 100 MW site only needs to curtail output to 25 MW on a given day, the control system will turn assets off and automatically log the change as an economic outage. Or, if a technician takes an inverter offline for cleaning and repair, the system will automatically log the change as a maintenance outage (Figure 3).

Figure 3: Renewable-specific SCADA software with built-in GADS reporting automates the collection, classification, and generation of report information resulting in more efficient, effective operations.

Complexity drives opportunity

Solar operations are far more dynamic than traditional power generation. That complexity is only increasing as more solar sites are coupled with battery storage facilities to create a dispatchable resource, and provide more flexibility in operation. Teams have moved far away from simple on/off control of solar generating capacity. Instead, today’s teams need to forecast the intensity of generation over multiple days, as well as follow the market to determine when to divert energy to the grid, send it to storage in batteries, or produce green hydrogen via electrolysis.

Managing that shifting economic case has brought the energy generation market to an inflection point. Operators can use guesswork, but in doing so they risk wasting money and resources, either when they over-generate and must curtail excess energy, or under-generate and must purchase energy to make up for shortfalls.

A better solution is to implement digital control technologies that integrate with forecasting tools and advanced control suites to enable the farm, site, or even fleet to automatically adapt to changes in weather and markets. Automation solution providers with decades of experience in the power industry have been developing these systems, and the associated algorithms, for many years. They will continually update those solutions as the requirements of the industry change, helping producers continually lock in competitive advantage, even in the face of changing markets.

Digitalization drives a changing future

As the solar market continues to grow and new technologies shape an ever-changing array of regulations, power producers will increasingly need digital technologies to help them navigate complexity and uncertainty in operations. Those technologies are already emerging today, with control systems and automation platforms built specifically for renewable technologies. Forward-thinking companies are now implementing these technologies to build the foundation that will give them the flexibility to maintain their competitive edge, regardless of changes in the years to come.

James Fraser has almost 25 years of automation experience in the power industry. As Vice President of Renewables, James is responsible for leading the continued development and execution of Emerson’s renewable strategy. His focus is driving the global growth of Emerson’s expanding renewable capabilities through the increased sales of software and automation technologies of the Ovation Green Suite of solutions and quality implementation of users’ clean energy portfolios including wind, solar, hydro and energy storage projects. James has a bachelor’s degree in Control Systems Engineering from the University of Sheffield, and a Master of Business Administration from the University of Cranfield.

James Fraser has almost 25 years of automation experience in the power industry. As Vice President of Renewables, James is responsible for leading the continued development and execution of Emerson’s renewable strategy. His focus is driving the global growth of Emerson’s expanding renewable capabilities through the increased sales of software and automation technologies of the Ovation Green Suite of solutions and quality implementation of users’ clean energy portfolios including wind, solar, hydro and energy storage projects. James has a bachelor’s degree in Control Systems Engineering from the University of Sheffield, and a Master of Business Administration from the University of Cranfield.

Emerson | www.emerson.com

Author: James Fraser

Volume: 2024 November/December

.png?r=8759)