Current AI Trends in PV Plant Monitoring

In 2022, U.S. electricity use was about 4,085 Terawatt-hours (TWhs). By 2035, that use is projected to reach 4,494 TWhs, and by 2050, 5,178 TWhs. As efforts to reduce carbon emissions increase, the use of solar energy in the U.S. is expected to grow from 3 percent of the electricity supply today to 40 percent by 2035, and 45 percent by 2050. Combined with the expanded use of renewable energy and battery energy storage systems, this significant increase in power demand will require the use of advanced AI-enhanced software and other technologies to manage energy plants effectively, and ensure optimal performance.

According to the International Energy Agency, “Power systems are becoming vastly more complex as demand for electricity grows and decarbonization efforts ramp up. […] One of the most common uses for AI by the energy sector has been to improve predictions of supply and demand. Developing a greater understanding of both when renewable power is available and when it’s needed is crucial for next-generation power systems […] That’s where machine learning can play a role. It can help match variable supply with rising and falling demand – maximizing the financial value of renewable energy and allowing it to be integrated more easily into the grid.”3

In the PV industry sector, AI tools and related technologies provide a faster and more efficient method of processing large amounts of data from PV projects. Insights from these analyses can improve asset management and produce powerful strategic insights for PV plant decisions to maximize return on investment (ROI). Some AI-based processes include automated inspections, performance analytics, energy forecasting, and demand response.

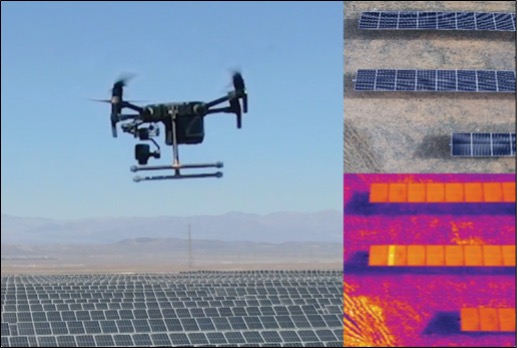

Infrared drones and smart PV inspection tools

Operating a PV plant requires proper maintenance of the onsite equipment to maximize power output. With thousands of modules and hundreds of inverters on a single site, this task is extremely challenging. Until recently, a licensed professional had to walk the site to take photos and infrared scans of sample modules. The expert would then provide general recommendations on how to fix or replace any damaged modules, and sometimes advise resetting power output expectations.

As these processes were time-intensive (since the modules had to be shipped to a third-party laboratory for testing to confirm any observed findings), it would take weeks before systemic issues were identified and resolved. This delay could impair project financing, any Power Purchase Agreements (PPAs), and construction timelines. Recent advancements in Infrared (IR) drones and AI-enhanced software have sped up these processes. Instead of manually collecting sample modules, fleets of IR drones can now scan entire PV sites, making inspections more efficient.

Drone flying over solar farm and infrared inspection shots taken by on-board camera, and electroluminescence tests imaging

AI-modeled software, such as “smart” PV inspection tools, then can quickly analyze the raw data. In just minutes, these tools can process thousands of images collected from IR flyovers, identifying various performance-affecting assets, classifying their importance, and geo-locating the faulty modules within the plant. These tools ensure that the results are delivered to project owners within a couple of days, enabling for faster response times. Time and money can also be saved by using mobile laboratories at the plant to conduct onsite testing of faulty PV modules.

“Smart” SCADA and Machine Learning tools

Asset performance analysis is another area where AI-enhanced software is helping to obtain more information from supervisory and control data acquisition (SCADA) systems. In the past, SCADA systems only produced monthly reports that offered a high-level overview of system health, but were unable to detect potential production loss due to downtime events or other issues. Today's AI-enhanced “smart” SCADA systems offer more accurate and relevant information along with detailed recommendations. These recommendations can include advice on the best times to wash certain module strings, and information on specific inverter issues, as well as the expected timeframe for critical failures.

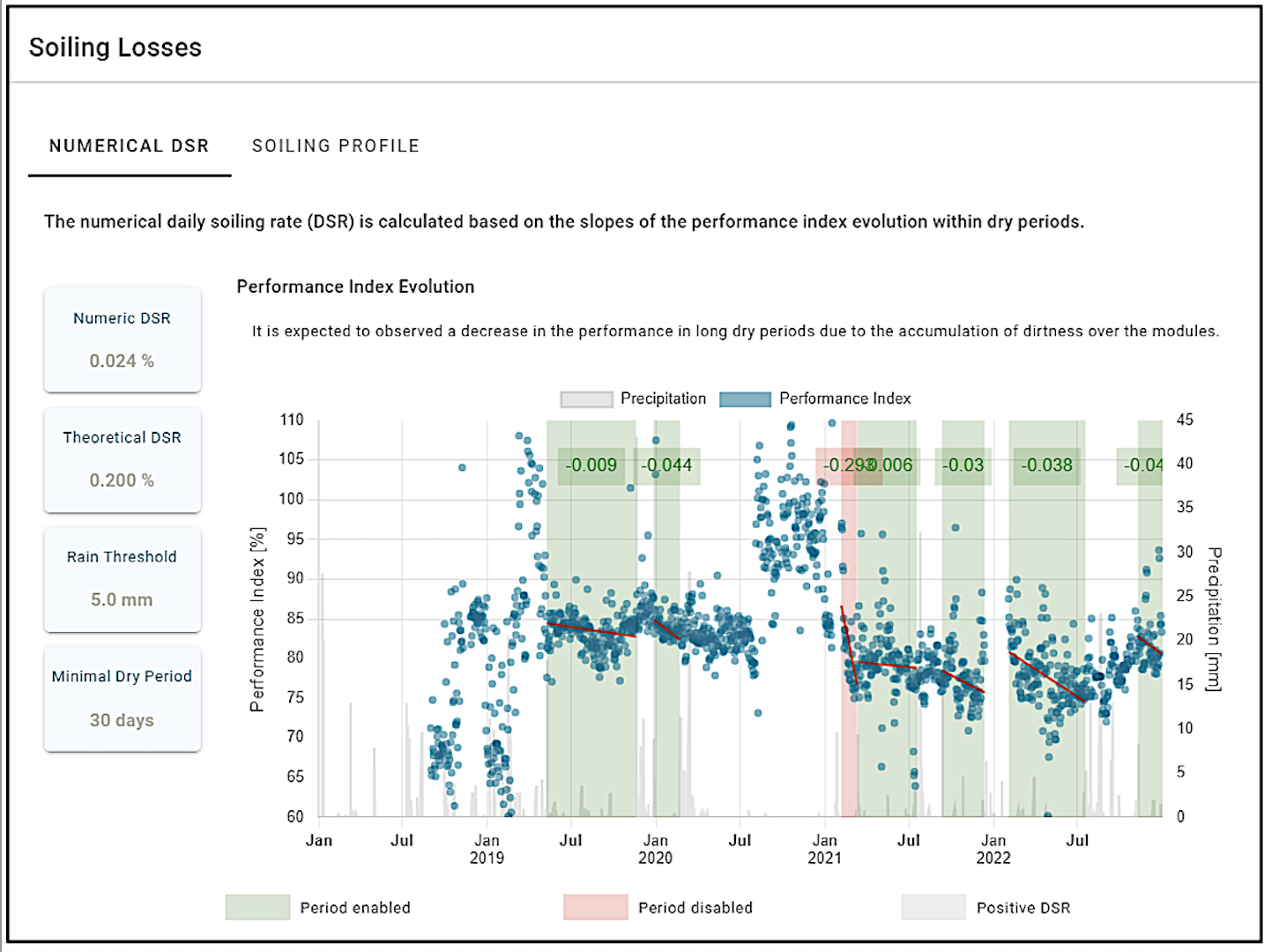

Similar to smart SCADA systems, stand-alone performance analysis has started to rely more on Machine Learning (ML) techniques. ML, a form of AI-enhanced software, provides detailed information on the kind of systemic issues described above. Data is often available at one minute (or even sub-minute) resolution across several years of operation. ML models can process this data for each component at every hierarchical level. These important insights have opened new frontiers for managing PV plants.

There are tools currently on the market that can calculate important metrics such as actual performance ratio (PR) for each component, how much energy has been lost during downtime events at the meter level up to the string level, and the optimal behavior of the different device types based on their historical data. These tools can also conduct separate analyses to determine losses due to various factors such as long-term system degradation, utility-enforced curtailment, soiled modules, and non-functioning single-axis trackers. Additionally, the tools can calculate actual AC losses between the inverter and point of interconnection.

Calculation of a site-specific daily soiling rate & realistic soiling losses based on asset production data.

Some AI-enhanced tools can also fine-tune forward-looking P50 expectations and identify the most likely causes of underperformance. Another attractive capability of these tools is their ability to process various types of information, regardless of the format. This means that if a portfolio consists of multiple PV plants with different SCADA systems, they can all be integrated into a single platform, thereby centralizing the information and providing a direct performance comparison across assets.

Module defect detection

Anomalies in solar panels can be identified using special cameras that capture IR and electroluminescence (EL) images. If defects are present in a module, specific patterns will be generated, allowing them to be identified and classified. These metrics can be used to create robust ML models capable of automatically analyzing and identifying the areas affected by the defects, and determining their impact on device performance.

Performance analytics

AI-enhanced algorithms can analyze data from sensors and other monitoring devices in real-time to identify inefficiencies and recommend adjustments to improve performance.

Energy forecasting

AI models can forecast the expected production output of PV projects, sometimes days ahead of real-time. This calculation depends on the quality of weather forecasts, and is used by the owners of power plants and utilities to plan daily operations.

Demand response

Utilities employ end-user consumption data to predict future demand on the grid. This enables them to determine how much energy will be needed moving forward. Depending on the situation, operating PV plants can be cut back due to oversaturation, or additional power stations (e.g., traditional power plants) can be powered up to meet energy demand.

AI applications are beginning to play a key role in transforming the solar PV industry. They are improving the efficiency and security of PV plants and driving the transition towards a more sustainable energy system. Looking ahead, we expect research on Large Language Models (LLM) to explore the impact of AI applications on our industry. There are exciting times ahead for clean power!

Lucas Viani is Head of AI at Energy & Industry Division, and Brian Custodio is Director of Data Science and Consulting at Enertis Applus+

Enertis Applus+ | www.enertisapplus.com

1-Statista Projected electricity use in the United States from 2022 to 2050 https://bit.ly/4bmTKds

2-U.S. Dept. of Energy Solar Futures Study Fact Sheet- https://bit.ly/3RISytK

3-International Energy Agency-Why AI and Energy Are the New Power Couple https://bit.ly/4eHv9mk

Author: Lucas Viani, Ph.D. and Brain Custodio, MSc.

Volume: 2024 September/October

.png?r=8388)