Hazard Control on Buildings with PV

UL 3741 was published in late 2020, and is now referenced in both the 2020 and 2023 National Electric Code (NEC) 690.12 B (2) as a PV Hazard Control System (PVHCS), another option to comply with rapid shutdown requirements on buildings with PV. The Photovoltaic Hazard Control System (PVHCS) listing allows systems to be designed up to 1000V without the need for module-level power electronics (MLPE).

Maintaining firefighter safety is part and parcel to the UL 3741 Safety Standard and is verified by the certification and testing requirements. Systems Listed to UL 3741 undergo rigorous testing to ensure they meet the requirements of the Standard, which is to reduce shock hazards in the case of firefighter interactions. This ensures that the equipment is safe under these abnormal conditions, enhancing overall safety during rescue or fire suppression efforts.

Cost savings

Racking Systems Listed to UL 3741 and approved with select string inverters that incorporate rapid shutdown, as mentioned, mitigate the need for MLPE. System costs can be dramatically reduced in a UL 3741 compliant design, saving on materials, installation time, and future O&M costs.

Using a string inverter rather than MLPE not only provides several cents per watt savings, but also cuts the number of cable connectors in half; fewer connections mean fewer points of failure. Additionally, polymeric-based ballast systems are becoming increasingly popular as they have fewer exposed metal edges, reducing the risk of wear-damage that could cause a ground fault. Minimizing exposed conductive parts and wiring are also key to a good UL 3741 design.

Safer solar

Underwriter’s Laboratories (UL) is a Standards development organization responsible for developing and writing U.S. Safety Standards. Certification for UL 3741 systems is done by nationally recognized testing laboratories (NRTL).

The below gives additional context and guidance on system design:

Rapid Shutdown of PV on Commercial Buildings

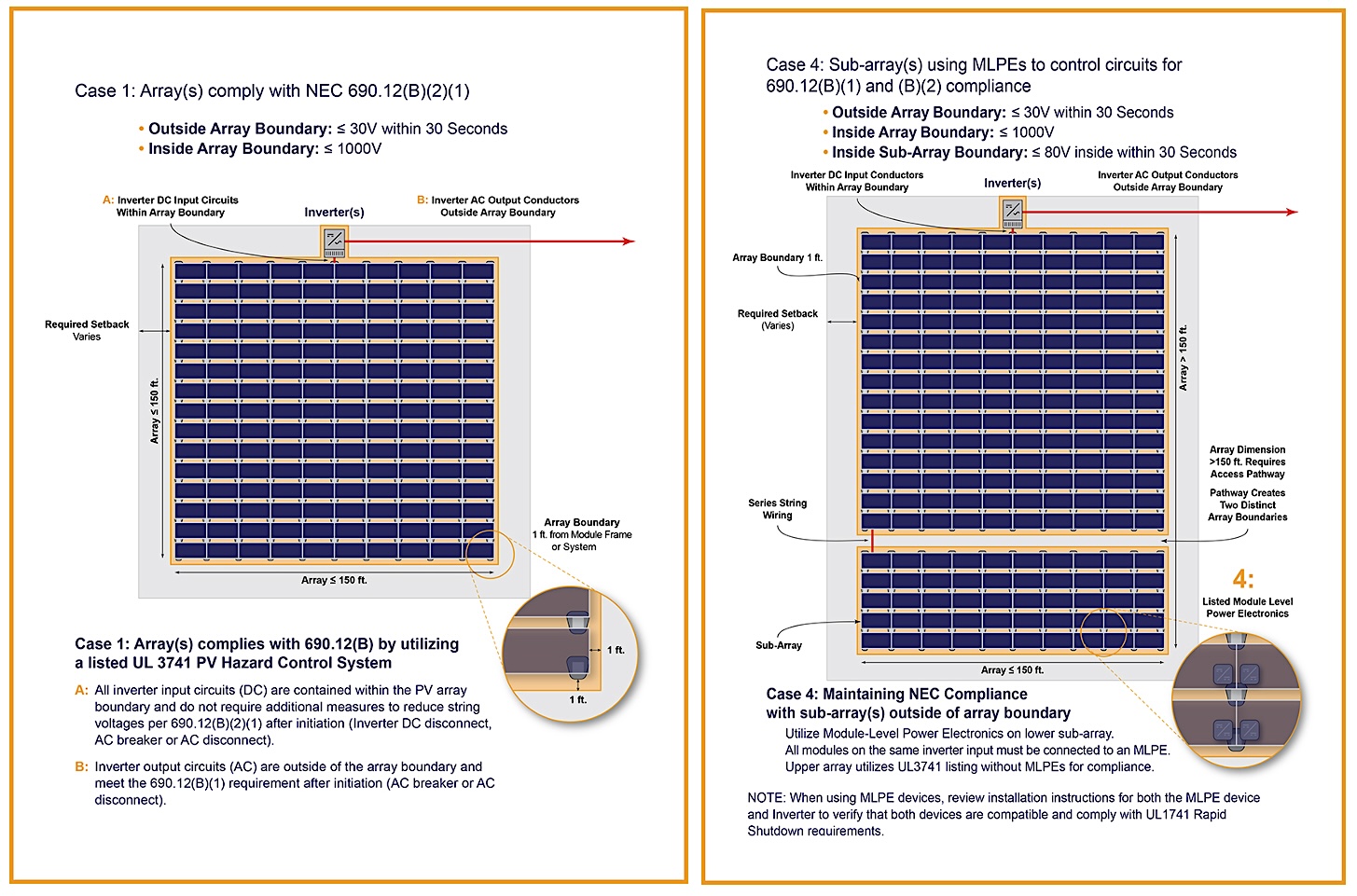

In the 2020 National Electric Code (NEC), “Rapid Shutdown” inside the array boundary has been updated to include “PV Hazard Control Systems (PVHCS)” as a method to comply with Rapid Shutdown requirements.

NEC 690.12 requires that all PV arrays installed on or in buildings shall include rapid shutdown functions to reduce shock hazard for Fire Fighters (FF) in accordance with 690.12(A) through (D):

(A) Controlled Conductors

(1) PV system DC circuits

(2) Inverter output circuits originating from inverters located within array boundary

(B) Controlled Limits

(1) Outside Array Boundary: ≤30V within 30 seconds

(2) Inside Array Boundary:

(1) Listed PV Hazard Control System (UL 3741)

(2) ≤80V within 30 seconds after rapid shutdown initiation

(3) PV array without exposed wiring methods or conductive parts

(C) Initiation devices

• Initiation device(s) shall initiate the rapid shutdown function of the PV system

(D) Equipment

• Equipment that performs rapid shutdown functions other than initiation devices, such as listed disconnect switches, circuit breakers, or control switches.

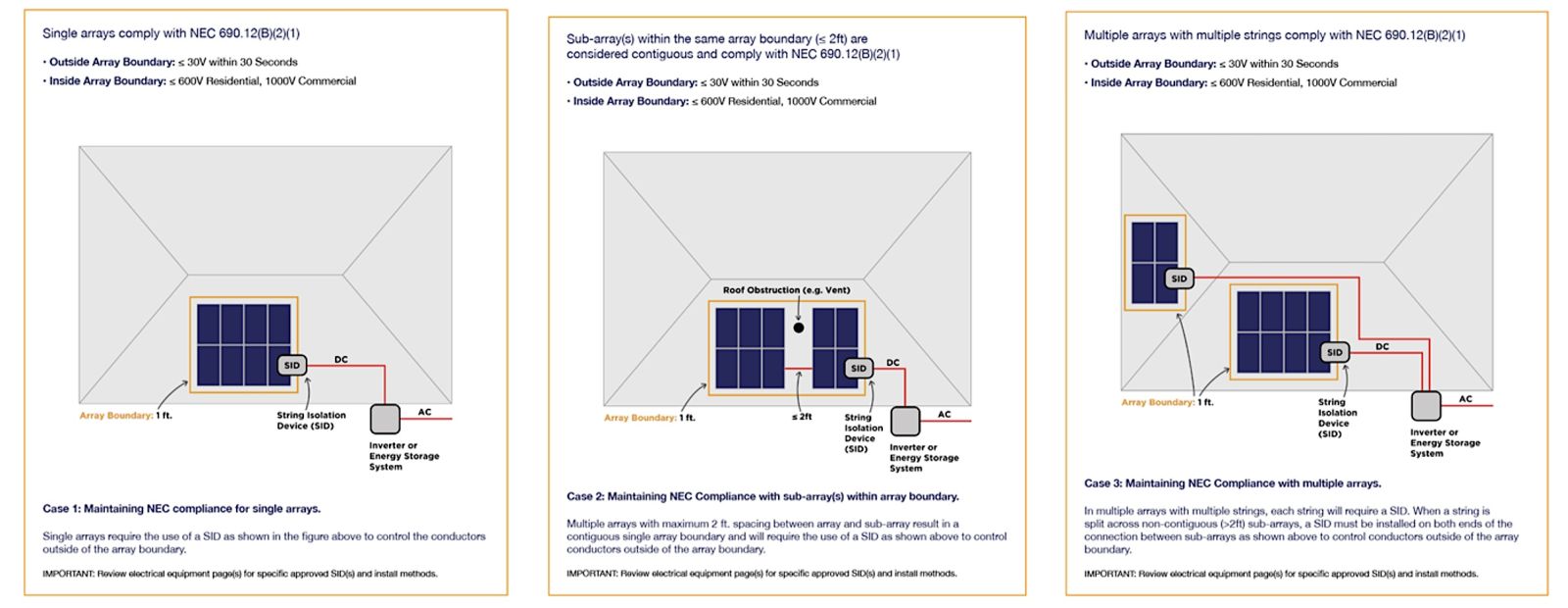

The simplest installation method to comply with NEC690.12 (B)(2) is to employ a UL 3741 system within a contiguous array — with one or more co-located inverters. All inverter DC input circuits must be within the 1ft array boundary (below left). Installations where sub-arrays are required and cannot be included within the 1ft array boundary can comply by alternative options (below right).

Rapid Shutdown of PV on Residential Buildings

PVHCS listed to 600V are now available for residential flush mount systems. In such a design, unless co-located with the array, all inverter and/or energy storage input circuits (DC) outside of the PV array boundary will require the use of String Isolation Devices (SID) to de-energize circuits leaving the array boundary per 690.12(B)(1) after initiation (DC disconnect, AC breaker or AC disconnect). Inverter and/or energy storage output circuits (AC) are outside of the array boundary and meet the 690.12(B)(1) requirement after initiation (AC breaker or AC disconnect). The case studies shown illustrate design parameters.

In conclusion, UL 3741 plays a pivotal role in advancing safety and cost-efficiency in photovoltaic (PV) systems on buildings. By allowing for the design of PV systems up to 1000V (600V Residential) without requiring module-level power electronics (MLPE), it provides an alternative approach to meeting NEC rapid shutdown requirements while reducing overall system costs. The rigorous testing and certification of systems under UL 3741 ensure that these systems meet high safety standards, particularly in emergency situations, thereby safeguarding both firefighters and buildings. The flexibility offered by UL 3741 compliant designs also streamlines installation and maintenance, enhancing both the reliability and long-term performance of PV systems. As the solar industry continues to grow, UL 3741 stands as a critical standard for creating safer, more efficient solar installations on buildings.

Glenn Woodruff is an Associate Product Marketing Manager with IronRidge, which designs and manufactures structural hardware for residential and commercial solar systems. Prior to his current position, Glenn represented IronRidge and Quick Mount PV for 6 years as the Territory Sales Manager for the Southeastern United States, and Caribbean. He resides in Palm Beach Gardens, Florida with his partner, Lori, son Anderson, and two dogs, Elvira and Otis.

IronRidge | www.ironridge.com

Author: Glenn Woodruff

Volume: 2024 November/December

.png?r=9759)