Shining a Light on Stored Solar and Battery Data

Photovoltaic (PV) solar energy generation has been a viable technology for decades, and, until recently, PV solar installations were limited in number and small in capacity, ranging from a few kilowatts (kW) to several megawatts (MW). Traditional fossil plants made up the majority of generation for supporting global power needs. However, in response to the increasing demand for clean electricity, regulated and independent power producers have been exploring ways to increase their renewable energy supply; a core element of that strategy is increased solar PV generation.

As PV solar power has grown in popularity, intermittency of output and grid stability has become a bigger concern. When sunshine is abundant, solar sites can have excess generation that may need to be curtailed and thus wasted. Or, during cloudy days or weather events, PV solar can struggle to keep up with forecasted output. This results in a production deficit that requires generation from unscheduled alternative sources, which could be expensive and impact revenue. To meet this dynamic environment and gain more control over uncertainty, many PV solar producers are adding battery storage to their portfolio (Figure 1).

Figure 1: Combining solar PV production with battery storage systems can help stabilize the grid, allowing fast response to fluctuations in energy demand, and by providing ancillary services such as frequency regulation, voltage control, and peak shaving.

While it is fairly easy to accumulate and store the data from solar farms and battery storage systems, companies seeking a competitive advantage recognize they need contextualized data to make better, more informed decisions. These companies are building a long-term plan for their solar and battery data, putting the foundational technologies in place now to drive more value from their data over the lifecycle of their assets.

A deluge of data

PV solar farms have panels, inverters, meteorological stations, substations, transformers, and more, with each independent component generating its own data. In large sites, this can easily reach hundreds of thousands of data points. Battery storage can increase those numbers exponentially, with some of the largest battery sites capturing over a million values. Adding bidirectional inverter communication to the equation creates a complex system that needs simplifying tools to determine an optimal charge and discharge schedule.

That data, while expansive, is also critical to advanced operations. It is the foundation upon which teams can build diagnostics and baselines of ideal operations, which empower them to build models to train operators, identify process aberrations, engineer new operating strategies, and improve performance and profitability — but only with the right tools. Teams using millions of data points from a historian can only perform basic analyses, but they can do much more with advanced analytical software tools (Figure 2).

Figure 2: Adding battery storage to solar PV farms creates a dispatchable entity that increases asset value by creating new economic opportunities that can be further exploited by forecasting and analytic tools.

Technology builds a foundation

The roadmap to taking advantage of PV solar and battery storage data is not exclusive. Organizations at any stage in their operations can find a level of technology that will start them on a digitalization strategy journey to help them make the most of their investments; a renewable energy producer can begin with simple software tools, and expand on them over time.

As an entry point, the right supervisory control and data acquisition (SCADA) software can help boost renewable production by calculating meaningful KPIs, collecting and contextualizing millions of data points, and showing critical information through operator displays. Automation partners with deep energy industry expertise can further help these organizations integrate pattern recognition solutions with their SCADA system to quickly and intuitively identify the real-world problems that impact a site’s ability to optimally operate.

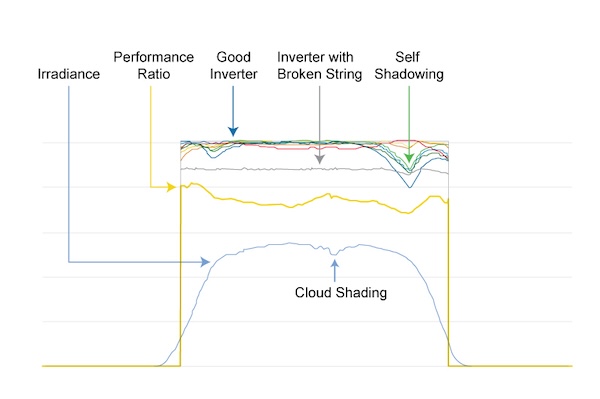

For example, an operator may not notice an inverter that has been degrading uncharacteristically over several months. Pattern recognition software can see the data trend by detecting minute step-changes, identify the problem, and alarm operators in the early stages to avoid a potential failure (Figure 3).

Figure 3: Leveraging proven, foundational software, such as purpose-built renewable SCADA, to extract and display contextualized data, can help detect developing site issues earlier in the failure curve that may not be visible or obvious to operators.

In a more advanced environment (i.e., one already using pattern recognition) teams can use digital twin simulation software to collect and further refine data in a risk-free environment. These teams can build baseline models of operation to identify and mimic the optimal output of a plant. Analysts can then run historical data through simulations to track and trend more complex anomalies and model degradation — caused by delayed maintenance, for example — including operational and financial impacts.

The most advanced companies are already considering the rise of artificial intelligence (AI) and analyzing how it will help them further refine their operating models. These companies are exploring advanced solutions to combine even more data from a wider array of sources to predict and identify problems, and to eventually empower AI copilots to intervene. For example, when an AI copilot identifies an issue like an inverter fan failure, it could potentially not only notify operators, but also automatically order the needed parts, and then schedule a technician to execute the repair using a computerized maintenance management system.

In parallel, leveraging a combination of site, market, and weather data with AI tools can lead to fully autonomous dispatch of solar PV and battery storage plants. This could result in optimal day-ahead operating schedules, while also “watching” the spot market for rewarding dispatch opportunities.

Capturing competitive advantage

There are a limited number of players in the PV solar generation and battery storage industry. However, as regulations change and incentives increase, so will the number of new companies looking to capitalize on emerging opportunities with digital solutions. The companies that win the future of renewable energy generation (solar and battery hybrid operations, in particular) will be those that can increase profit by dispatching power efficiently across multiple transmission authorities or system operators.

To be more competitive and responsive, these companies will need to make better use of the data for more effective decisions across their fleets. Currently, not every company is equipped to do this, but every organization can begin by putting foundational modern technologies in place that will make such a transition possible as the market gets more crowded. Those technologies will improve performance today, while simultaneously setting organizations up for success in the future, a win-win scenario for the whole industry.

Brett Benson is the director of global renewable solutions business development for Emerson’s Power and Water Solutions business. He possesses over 30 years of extensive power and automation industry project engineering and management experience with many types of power generators and fuel sources, with a focus on global, strategic renewable projects. In his current role, Brett helps to create value-add, purpose-built strategies for all renewable assets, with a focus on solar PV and battery energy storage. Brett received his Electrical Engineering Degree from Auburn University.

Emerson | www.emerson.com

Author: Brett Benson

Volume: 2024 July/August

.png?r=6433)