Solar’s Risk Takers: Danger for installers skyrocket with demand

The clean energy transition is advancing rapidly, with renewables projected to become the largest source of global electricity generated by 2025. Solar photovoltaic (PV) and wind energy will account for 95 percent of this expansion[1]. With increased demand for solar energy and solar arrays, however, comes increased safety hazards for solar installers, including slips, trips and falls, electrical hazards, extreme weather, and burns.

Understanding the jobsite risks

Similar to roofers, solar installation workers are vulnerable to the highest rates of fatal falls in the construction industry. In fact, between 2020 and 2021, roofing fatalities increased by 15 percent, along with the rise in solar installations[2]. From 2011 to 2019, 650 PV installers were injured while on the job. Those dangers will only go up: the U.S. Bureau of Labor Statistics expects solar array installation jobs to grow 51 percent by 2029[3].

Ranked number four on the Occupational Safety and Health Administration’s (OSHA) list of most dangerous fields of work, the construction industry is especially prone to falling objects, and slips, trips, and falls. One of the biggest dangers resulting from these accidents is traumatic brain injuries (TBIs), which can have life-altering and even deadly repercussions. According to the CDC, there were 214,110 TBI-related hospitalizations in 2020, and 69,473 TBI-related deaths in 2021.[4]

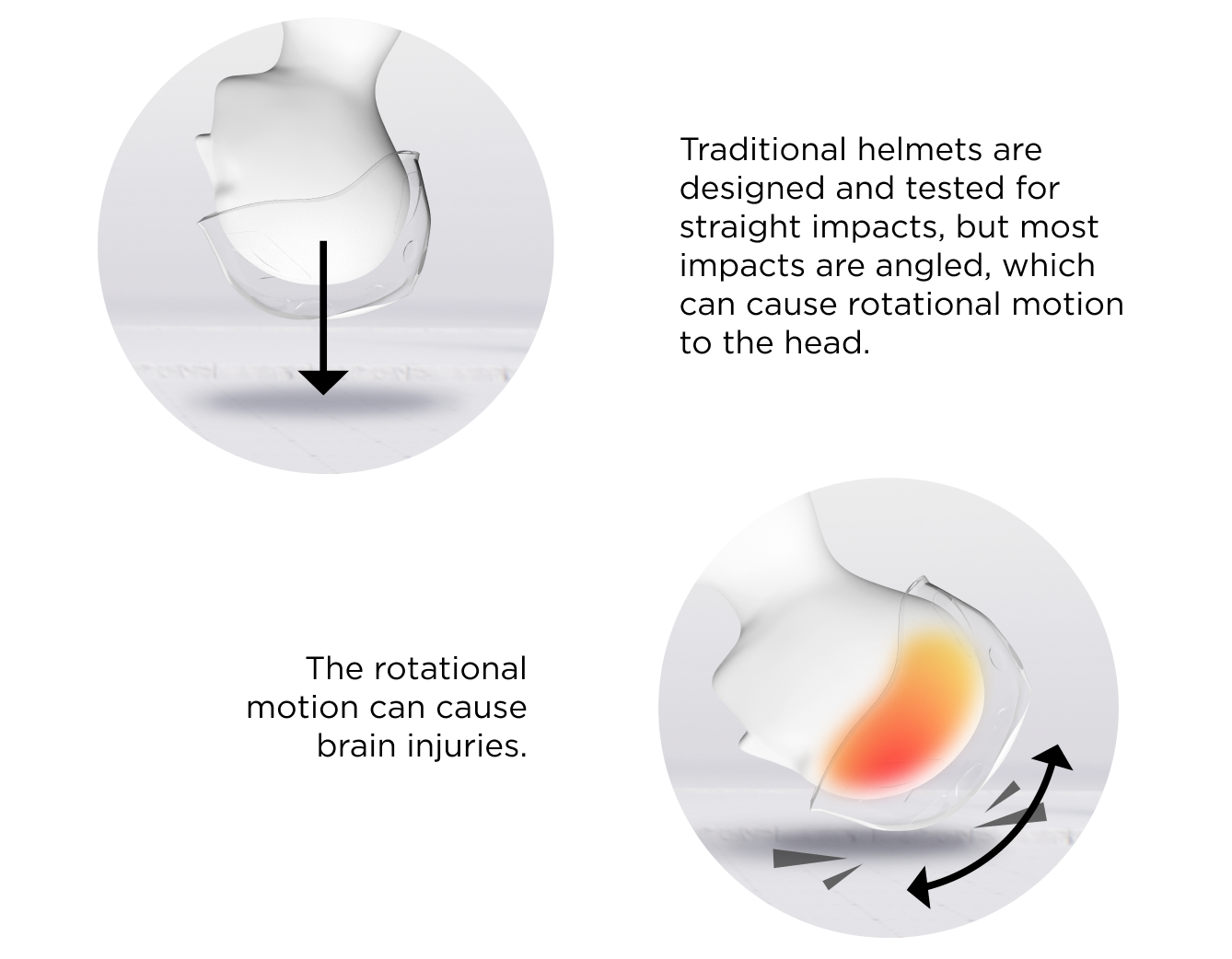

This is a huge issue for the solar industry and construction sector in particular, as it has more TBIs than any other industry[5]. These accidents are so deadly because when workers fall and hit their heads, the impact is likely to take place at an angle, which can put the brain at risk of rotational motion. The brain is much more sensitive to rotational motion than linear motion; it can cause severe brain damage or possibly death[6]. As a result, when rotational motion is a factor, even impacts to the head that may seem light can lead to harmful brain injuries. It is imperative that construction workers installing solar panels receive the proper education about the risks they face on the job, and how to properly protect themselves.

This is a huge issue for the solar industry and construction sector in particular, as it has more TBIs than any other industry[5]. These accidents are so deadly because when workers fall and hit their heads, the impact is likely to take place at an angle, which can put the brain at risk of rotational motion. The brain is much more sensitive to rotational motion than linear motion; it can cause severe brain damage or possibly death[6]. As a result, when rotational motion is a factor, even impacts to the head that may seem light can lead to harmful brain injuries. It is imperative that construction workers installing solar panels receive the proper education about the risks they face on the job, and how to properly protect themselves.

It is critical that these workers are aware of their exposure to the myriad fall hazards from their close proximity to roof ledges and elevated surfaces, as well as working on scaffolds and ladders. In addition, solar installations are usually still done in bad weather where water or ice can lead to increased slip and trip hazards[7].

Residential rooftops often pose a greater risk than industrial rooftops due to steeper slopes and lack of fall protection options. Residential roofs usually offer very limited fall protection options since it is not ideal to attach fall protection anchors and/or guardrails to a residential roof without the owner’s permission. Commercial roof owners usually allow for the use of fall protection anchors, guardrail systems, or mobile anchor points.[8].

Current industry construction safety standards

Due to the dangerous nature of installing rooftop solar panels, OSHA has specific fall protection requirements for their construction vs. their maintenance, which is covered under general industry requirements. PV installers working more than six feet above the ground must be protected by falls from one of the following three methods: Guardrail systems, safety net systems, or personal fall arrest systems[9].

Proper head protection

While OSHA requires head protection to be worn by employees working in areas where they are at risk for head injuries from impact, falling objects, or electric shocks and burns[10], a standard helmet does not account for rotational motion. The ubiquitous and traditional hard hat was introduced over 100+ years ago; it only protects the wearer on the top of the head, not against rotational motion.

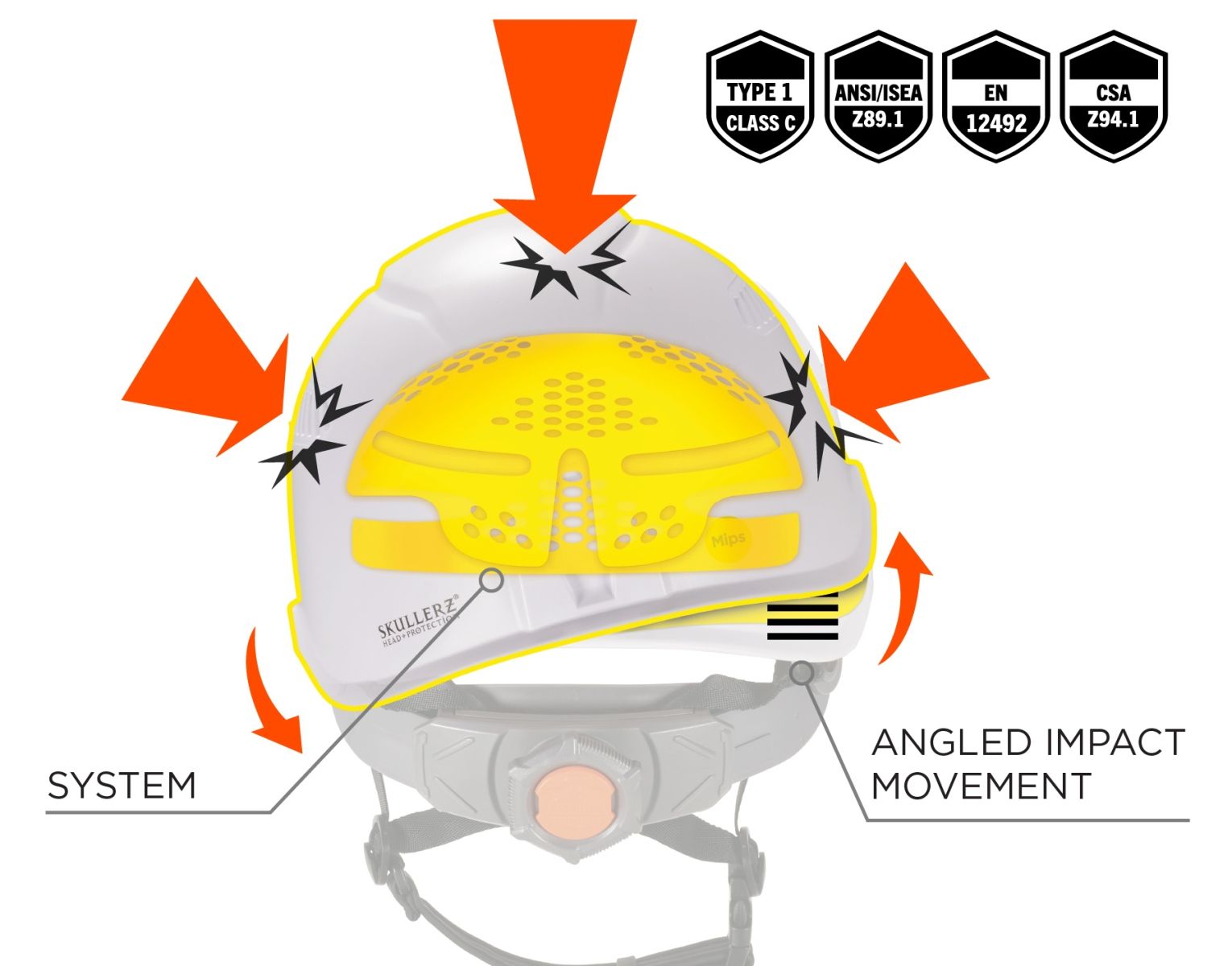

It is critical that workers use proper head protection on the job. When choosing a safety helmet, it is important that helmet wearers consider a helmet equipped with a rotational motion mitigating system. This system should allow the material inside the helmet to move and slide relative to the worker’s head, with the intention of redirecting the rotational motion away from the head to reduce the risk of severe injury.

Solar installers face a number of risks on the job on a regular basis. The first step to improving safety begins with education on the jobsite hazards, including TBIs and rotational motion, and how to implement the best safety measures to reduce head injuries.

Joe Brandel is Business Development Manager for North America Industrial Safety Market at Mips, focused on helmet-based safety. He has been in the construction and industrial safety business for over twenty years. Specializing in head protection, hand protection, fall protection, and other personal protective equipment, Joe has provided training for large and small companies throughout the Midwest. He has also provided solutions for a variety of industries, which have not only helped reduce costs, but most importantly, created safer working environments for employees.

Mips | mipsprotection.com

[1] https://www.iea.org/news/massive-expansion-of-renewable-power-opens-door-to-achieving-global-tripling-goal-set-at-cop28

[2] https://www.nextbigfuture.com/2021/07/2020-fatalities-for-us-roofers-increased-15-as-solar-roof-installations-increase.html

[6] Kleiven, S (2007). “Predictors for traumatic brain injuries evaluated through accident reconstructions,” Stapp Car Crash J, vol. 51, pp. 81–114, Oct. 2007.

[7] https://simplifiedsafety.com/blog/solar-installation-safety/?srsltid=AfmBOorsKFyTzIQS1NRJ8BHzaU1spVAoLqihNSlH8MwXYRXO8zrEpM4k

Author: Joe Brandel

Volume: 2024 November/December

.png?r=8489)