The Sound of Solar

In a push towards sustainability, many coal- and gas-fired power plants across the U.S. are being replaced with environmentally friendly and renewable energy (RE) sources like wind and solar. However, there are plenty of environmental hurdles for RE projects to overcome to get through the permitting process. One major environmental side effect that plagues wind farms is noise emissions, evidenced by some projects not passing the permitting stage, or being shut down due to bothersome noise. Solar power, a quieter alternative, has gained popularity across the country for many reasons, aside from noise. Photovoltaic (PV) or solar energy generation sites are popping up on highway median strips, brownfields, greenfields, and even agricultural lands.

But, not so fast! At first look, one would think that a solar energy facility generates NO sound. There are no large moving parts like the large blades of a wind turbine or combustion-producing impulsive engine noise. The most visible part of the solar facility is the large solar panels, and these indeed produce NO sound. However, there are noise-generating equipment at solar facilities; they are inconspicuously sited on small concrete pads (as shown in Figure 1). These pads hold various pieces of equipment which typically include transformers, inverters, and switchgear. The acoustics professional will know the noise emissions details of each equipment type.

Like any other energy-generating or industrial facility, the solar farm will need to be compliant with state, county, and/or municipal noise codes. Facilities far from residential properties should not require consideration of noise. However, if the facility fence-line is within 1,000 feet of a noise sensitive receptor such as residences, schools, and places of worship, you should consider further review by an acoustics professional. Before undertaking a full noise study, the next step might be to look closely at the applicable regulations and ordinances, which can have various forms. Most of the Northeast states have policies regarding noise, including New York, New Jersey, Connecticut, Massachusetts, Maine, and Rhode Island. Most of the Southeast states have noise limits at the county level. Wherever the project is situated, it will need to meet the most stringent of those three jurisdictional limitations (town, county, and state).

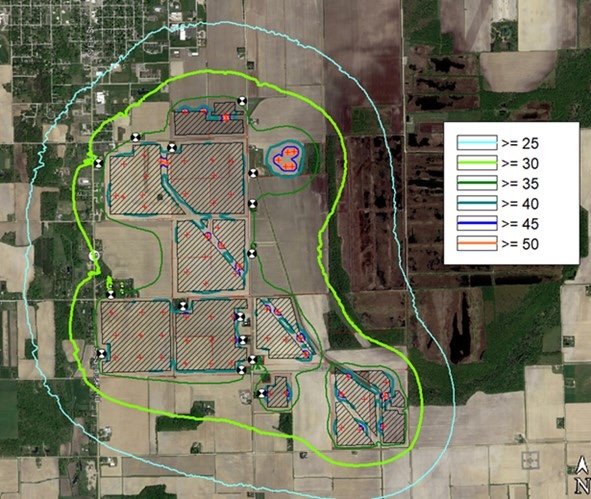

3D acoustic model of a solar facility with sound contours from 25 to 50 dBA (photo credit Acentech)

One thing that the acoustics professional needs to watch out for is a “Pure Tone” criterion, which can become the primary obstacle in achieving compliance. Some jurisdictions — like the States of Connecticut, Massachusetts, and Maine — have such requirements. While most of the equipment used at a solar facility is noiseless (like the solar panels), the rest produce either broadband, tonal, or both types of sound. Broadband sound is sound with a contribution of acoustic energy at all frequencies. Examples of broadband sources are some mechanical (HVAC) equipment, cooling fans, pumps, and even the water fountain at the park. Tonal sound is sound produced at a single frequency. Examples include fingernails on a chalkboard, a police siren, whining fan, damaged car bearing, squealing brakes, and lastly, the electrical hum of solar facility electrical equipment.

Solar facility transformers are used to step-up the voltage for easier transmission into the local electrical grid. There are three sources of noise from within the transformer: (1) core noise, (2) coil noise, and (3) fan noise. The core and coil noise are caused by electromagnetic forces that occur two times for every cycle of AC power. Like the inverters, this results in 120 Hz primary sound source, along with harmonics (as noted above). The third source of sound is the cooling fan(s) mounted outside the transformer, usually directed across the fins of a heat sink. While the cooling fans can be the most significant source of overall broadband A-weighted sound, “…it is almost always the pure-tone transformer noise and not the broadband fan noise that is objectionable”[1].

To determine if the project will be compliant, the acoustics professional may suggest analyzing the solar facility using one of the 3D acoustic modeling software tools. The acoustician will need the equipment “source” sound levels provided by all manufacturers. The software allows importing terrain features, modeling buildings, and other things that attenuate and diffract sound. The software then provides sound levels at any receptor location and sound contours (as shown in Figure 2). Now you are ready to consider noise control features.

The easiest — and least expensive — form of noise control at a solar facility is to put the sound producing equipment in the center of the facility. In general, this is the best location for sound output without knowing anything about a specific site. However, if one side of the solar site was residential and the other side was unoccupied or industrially zoned, placing the sound producing components on the industrial-zoned side would be beneficial.

While quiet transformers and inverters exist, they are generally not a good option for most developers due to their premium cost. Therefore, the second line of noise control would be noise barriers. The most aggressive sound control treatment for transformers and inverters is a full enclosure, or even a building. Due to the heat generated by both devices, a forced air ventilation system would be needed. However, the fans used in these cooling systems may be louder on an A-weighted basis than the electrical side of the hardware.

A solar facility’s electrical equipment pad (photo credit Acentech)

One thing in favor of solar facilities is that most of them only operate during the day, although some facilities with battery storage components could result in transformer and inverter operation during the night. This is an important consideration because excessive noise at night is usually a bigger issue for residential abutters. In these cases, there will be a real need for acoustic evaluation and noise control with respect to nighttime operations of solar energy components. Even working through the steps above, a noise-compliant facility can be designed with the proper planning and consideration of both the site and the community requirements.

Michael Bahtiarian is a Principal at Acentech, a multi-disciplinary acoustics, noise, technology, and vibration consulting firm. He is a fellow and board certified by the Institute of Noise Control Engineering (INCE-USA), and currently serves as the organization’s immediate Past- President. He can be contacted at [email protected].

Acentech | www.acentech.com

FIGURE 1: A solar facility’s electrical equipment pad

(photo credit Acentech)

FIGURE 2: 3D acoustic model of a solar facility with sound contours from 25 to 50 dBA

(photo credit Acentech)

[1] Ver, Istvan L. and Douglas W. Anderson, “Characterization of Transformer Noise Emissions; Volume 2 Substation Siting Guide, Bolt Beranek and Newman Report 3306, Prepared for Empire State Electric Energy Research Corporation, dated July 1977

Author: Michael Bahtiarian

Volume: 2024 July/August

.png?r=8905)