Water Scarcity May Hinder Global Solar

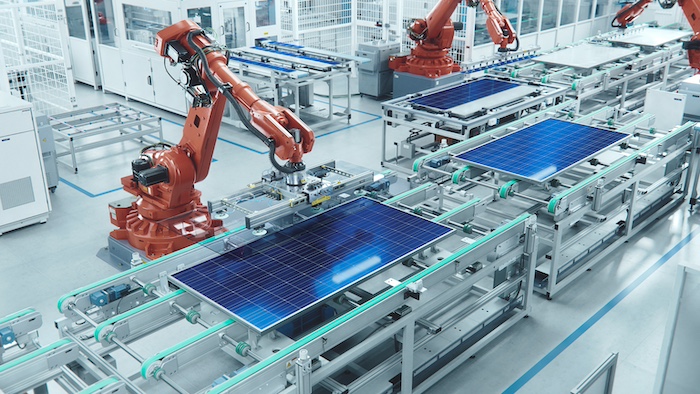

With the energy transition now officially in the fast lane, solar energy will soon represent the backbone of the global energy system. Already, solar is on track to make up more than half of global electricity generation by 2050, with more than 510 GW added in 2023 alone. This surging demand is rapidly transforming economies, underpinned by the growing need for robust manufacturing capacity.

As the race to build domestic supply chains heats up, manufacturers everywhere are facing a new challenge: the need to efficiently manage and conserve water to protect local communities and the environment. It’s an issue that hasn’t attracted significant mainstream concern — yet — but as water-intensive photovoltaic (PV) manufacturing continues ramping up and countries become increasingly prone to climate-fueled droughts, water scarcity could pose a real threat to production.

The good news is that manufacturers have the chance to proactively mitigate concerns by implementing up- and downstream water management processes and technologies, which are now broadly available and highly cost-effective, providing a means of reaching sustainability targets.

Manufacturing fever goes global

Few industries can claim a success story like solar PV, with annual manufacturing capacity expected to hit more than 1,000 GW in 2024 — an unprecedented boom in just a few years. For now, the overwhelming majority of solar manufacturing occurs in China, including over 80 percent of all polysilicon, wafer, cell, and module development. Other countries, however, are quickly ramping up their own industries, eager to ensure economic competitiveness and shore up their domestic supply chains amidst growing geopolitical turbulence.

Regions all across the world, including Europe, North America, South Asia, Africa, and the Middle East, have begun prioritizing PV supply chain diversification, with many passing legislation to stimulate domestic growth. One report even found that a few countries have reached cost parity with Chinese solar manufacturers, showcasing how quickly the global market is diversifying. At the same time, 2023 was just named the hottest year on record, putting growing pressure on the world’s freshwater supply at a time when manufacturers are looking to accelerate their operations and increase their water uptake.

While some countries will face more severe droughts and water shortages due to climatic differences, all will face a level of disruption. Rising temperatures, paired with increased manufacturing activity and growing populations, is a recipe for water scarcity. And since industrial use is deprioritized when freshwater is hard to come by, this will inevitably lead to expensive shutdowns for solar manufacturers bound by inefficient water uptake and treatment processes.

Impetus for water conservation

Manufacturing commercially available solar PV, regardless of brand or panel efficiency, requires significant water volumes; it’s used for etching, cleaning, and cooling, among other purposes. Solar manufacturers also have wastewater discharges that need to be carefully managed and reduced (another water-intensive process) to comply with stringent regulatory requirements and prevent environmental contamination. Water recovery for secondary and tertiary usage is, therefore, critical to enable manufacturers to massively cut down on uptake and treatment waste while reducing climate liability.

Ultrapure water, for instance, is essential for cleaning and etching PV systems (which enhances solar cell efficiency), but this generates substantial wastewater volumes in the form of reverse-osmosis reject and ion exchange regeneration brines. Simultaneously, the manufacturing process of solar PV electrical contacts and wiring requires the use of metals, with aluminum, copper, and silver being particularly important. To eliminate impurities during processing, cleaning solvents like nitric or hydrochloric acid are employed. The resulting wastewaters are highly acidic and contain residues that demand treatment. Having the right equipment and systems in place to do so effectively can make a world of difference in manufacturers’ ability to navigate water restrictions.

Fighting climate change is at the heart of what the solar sector does, but it’s critical that manufacturers and other stakeholders not lose sight of other challenges. As one of the basic necessities for life on Earth, freshwater demands careful management, especially by heavy industrial users. Maximizing water conservation and reducing necessary discharges will ultimately benefit solar manufacturers, allowing them to get ahead of impending regulations, and ensure reliable production that can meet the demands of today’s ambitious developers. The time is now for the solar sector to embrace water conservation.

Prakash Govindan is Co-Founder and Chief Operating Office of Gradiant, which helps customers minimize their water footprint by reducing water consumption, reclaiming valuable resources, and renewing wastewater so it can be returned to nature.

Gradiant | www.gradiant.com

Author: Prakash Govindan

Volume: 2024 May/June

.png?r=7639)