Weathering the Terrible Twos: How wind combined with hail or overcast gang up on solar trackers

If someone someday writes a history of the solar tracker industry, the author will surely tell of creativity and hard work by thousands of engineers and scientists, over many years, to make trackers more impervious to extreme weather, while also pushing cost down and energy production up.

It’s fun and gratifying to be part of that team – an international collective who have mostly never met each other.

(And I’ve always taken pride when telling my kids about my work!)

The weather aspect of this story is complicated – developing hardware and software to enable trackers to withstand extreme conditions including wind, overcast, cold, snow, and hail. But what’s really complicated is two or more weather events happening at the same time.

And when you put large numbers of trackers – up to 10,000 or more at a single site – into operation for 30 or 40 years or longer, it’s inevitable that whatever can happen, will happen. This complicates both the structural design and the functionality requirements (the software) immensely.

The objective is to protect both the trackers, and whichever modules are chosen by the system designers, 24/7/365, under any combination of weather conditions reasonably likely for the 30 to 40-year life of the solar power plant.

For example, you may reasonably expect wind and hail.

Wind alone is a complex matter. Steady wind poses one kind of risk, wind gusts another, and changes in wind direction require more intelligence from the tracker control system. Some trackers are prone to “galloping” – periodic twisting of the tracker in response to gusts – and require solutions to minimize that risk. Most tracker control systems deal with wind by going to a wind stow position when the steady wind exceeds a given speed, or if three-second gusts exceed a higher threshold. The best wind stow position may change depending on conditions such as the direction of the wind. It is also common for a tracker’s range of motion – such as 120 degrees, from 60 degrees east of horizontal to 60 degrees west of horizontal – to be reduced gradually as the wind rises toward that steady wind threshold.

The challenge is even more complicated when wind is combined with another weather event, such as snow or hail.

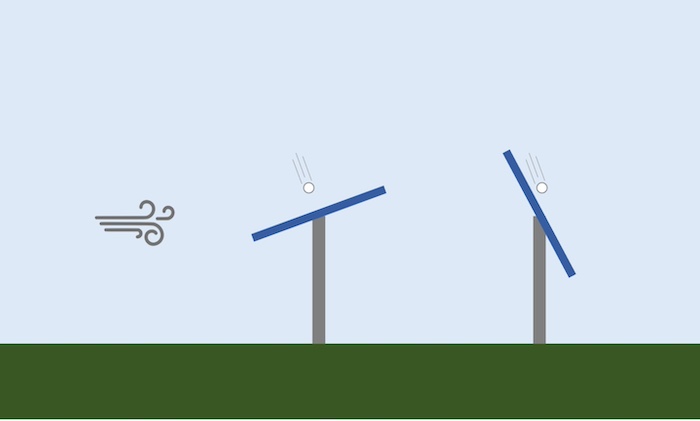

Hail in particular poses a challenge, since minimizing wind risk generally means facing the modules into the wind, while hail risk is minimized by facing the modules away from the wind. Tracker angles chosen to minimize risk of damage in high winds vary from 0 degrees – that is, horizontal – to 30 degrees. Both modules and trackers are strongest when the front of each module is facing into the wind, so ultrasonic anemometers have a big advantage as they report not only wind speed but also wind direction.

In the event of large hailstones in low wind, the hail stones tend to fall nearly vertical. Small hailstones in high wind will fall up to 30 degrees from vertical. In other words, tracker angles which minimize wind risk put the modules nearly perpendicular to the trajectory of the hailstones, and more-or-less maximize hail risk. Similarly, the angle which minimizes hail risk – modules at high tilt and facing away from the wind – maximizes wind risk.

Figure 1: Wind risk is lower on the left tracker, but hail risk is lower on the right tracker.

When both hail and high winds occur at the same time – which is common in much of the continental US – sophisticated methods are needed to minimize the total risk.

Short-term wind and hail forecasts, along with local real-time wind speed and direction data, can enable effective risk mitigation strategies. If a tracker control system gets the data it needs from those wind and hail forecasts, and gets that information at the right time (typically 15 to 30 minutes in advance of the hail), and if the control system has software which takes into account weather data and the capabilities of the tracker (including range of motion and motor speed) then both wind risk and hail risk can be minimized — generally without additional hardware cost.

Some market reports indicate that Texas was the biggest solar state in 2023, and likely to be the biggest again this year. Texas gets more hail than almost any other state. So, a focus on wind and hail is timely and will help owner/operators to get insurance at lower cost.

This wind/hail risk mitigation strategy is an emerging and value-adding feature of advanced tracker control systems.

Another odd couple is wind and overcast.

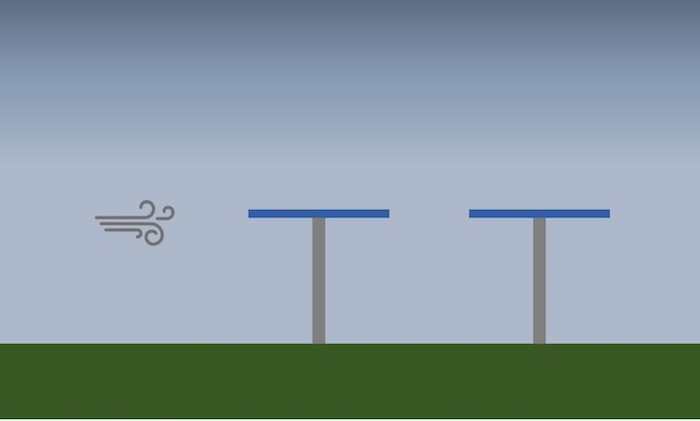

In overcast conditions (not passing clouds) energy production can be improved by not tracking the sun. Irradiance in these circumstances comes not from a single part of the sky (the sun) but from a diffuse cloud layer.

Tracking the sun does not increase production. In fact, it can even reduce production, because at angles far from horizontal, the modules are not exposed to the whole sky. Highest energy production in overcast conditions comes from exposing each module to the whole sky, even as gray as it is. In this case, production can be increased by putting the modules at an angle nearly horizontal.

But some trackers – and some modules – can be at risk at tilts near to horizontal; some trackers experience “flutter” at such low tilt angles, even at low wind speeds. The need to avoid very low angles for an extended period of time may require software to maximize production while keeping the modules at a slightly higher angle (but still close to horizontal) and then return to tracking as soon as there is visible sun.

Figure 2: Overcast conditions mean highest production at horizontal tilt, posing wind risks for some trackers.

The design of the tracker structure can make these challenges easier by reducing or eliminating some of the problem modes. For example, a tracker structure may not be vulnerable to flutter or galloping due to correct balancing of factors such as friction and torsional strength.

The more failure modes a structure has, the more sophistication is required in the software, and the more risks there are when some unlikely combination of weather states occurs. Note that the complexity added by the risk of two or more weather conditions occurring at the same time imposes added testing requirements – everything that could pose a problem must be checked!

Utility scale customers increasingly expect trackers to be proof against even those unlikely series of events that fall within a location’s climate profiles. Fortunately, tracker suppliers are stepping up to meet that expectation.

Someday, somebody ought to write another chapter in the solar tracker history.

(But no matter how good it is, I probably won’t be able to get my kids to read it.)

Matt Kesler is Director of Solar Technology at OMCO Solar. Built on 8 decades of steel manufacturing, OMCO Solar has delivered 10.5 GW of factory-direct, high-quality solar mounting structures nationwide.

Matt Kesler is Director of Solar Technology at OMCO Solar. Built on 8 decades of steel manufacturing, OMCO Solar has delivered 10.5 GW of factory-direct, high-quality solar mounting structures nationwide.

OMCO Solar | omcosolar.com

Author: Matt Kesler

Volume: 2024 May/June

.png?r=4240)