Efficient Load-Out of First Wind-Powered Offshore Gas Platform in the Dutch North Sea

The N05-A platform is the first offshore gas platform in the Dutch North Sea to be powered entirely by wind power – harnessing electricity via cable from the nearby 113.4 MW Riffgat offshore wind farm. The platform is part of the GEMS (‘Gateway to the Ems’) project, whose focus is the development of field N05-A and other fields in the area, situated in the waters on the border of Netherlands and Germany. The electrification of the N05-A platform is expected to reduce carbon emissions by over 85% throughout the project's duration.

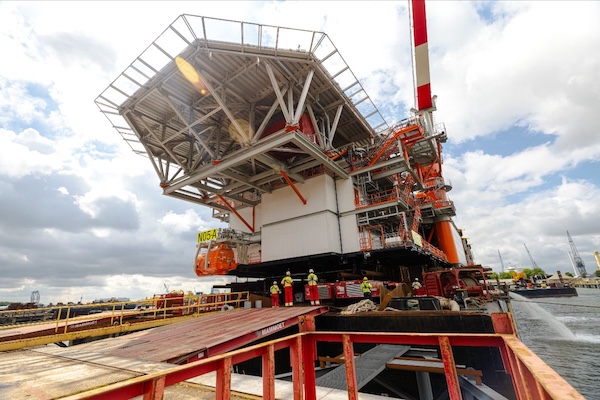

Mammoet was approached by HSM Offshore to support the load-out of the 3,050t N05-A topside, and 3,150t jacket, at HSM’s quayside fabrication facility in Schiedam, Rotterdam.

Mammoet’s scope for the project was to successfully load-out both components onto a barge for shipping to sea. Offshore sailing and installation were managed by ONE-Dyas, the owner of the platform.

Mammoet’s engineering approach allowed the jacket to be assembled more efficiently, close to its installation location, and reduced the lead time for construction.

Assembly and weighing of the jacket and topside realized with mobile cranes, conventional trailers and SPMTs

The first operational phase of the project was to support the movement and assembly of the jacket, which was fabricated and assembled in two parts.

Mammoet supported the heavy transport and upending of the jacket’s rows with four mobile cranes carrying out the lifts: two LTM 1650 (650t) cranes and two LTM 1450 (450t) cranes. The installation of its pile sleeves was completed using a 750t mobile crane.

Once in the correct position, the top section of the jacket was moved to the quayside where heavy lifting was performed by two sheerlegs. This created the space for the bottom section to be driven underneath so the two parts could be joined.

Self-Propelled Modular Transporters (SPMTs) were driven underneath the topside. These SPMTs drove the structure outside the fabrication facility and onto the quay. Mammoet then supported the installation of a pedestal crane onto it using conventional trailers and mobile cranes.

With both the jacket and topside complete, both were picked up by SPMTs and their final weights were determined by using Mammoet load cells. The load-out operation could begin after the weighing of both structures.

Shipping together both parts of the offshore gas platform to meet the schedule

One of the biggest challenges of the project was the load-out phase. Normally, for loadouts of this type, a barge would receive either a topside or a jacket; not both together. However, for this project both structures needed to be loaded-out onto the same vessel, to shorten the overall schedule.

This created space and engineering challenges, as the team had to also allow room to install pumps and winches onto the transport vessel. The combined loads also meant conventional mooring methods couldn’t be applied.

“The mooring was quite critical, and we had to do a lot of engineering,” explains Sven Segeren, Project Manager at Mammoet. “Normally, we would use a configuration of winches to moor and stabilize the vessel, but that wasn’t possible because of the force of the considerable loads.

The loads on the winches were too high and the bollards not strong enough, so a small spud leg barge was used to secure the vessel and keep it in position prior to, during and after load-out”.

It took five days to prepare the main barge – to install the ballast equipment, perform the pre-ballasting, and check the sailing conditions to the final location.

The load-out operation of the jacket foundation and topside was completed in just two days. Four trains of 32 axle line SPMT trailer were used for the movements.

Due to factors beyond the project’s control, the date of execution was unknown for a significant period of time. Therefore, Mammoet was asked if it could prepare a temporary load-in venue, so the next project at the HSM Offshore yard could continue unimpeded.

The team prepared Mammoet’s own yard in Schiedam, next door to HSM Offshore, to perform a load-in of the topside and jacket. An area was prepared to temporarily house the components, equipment was reserved, and necessary engineering plans made.

This space was ultimately not required. However, Mammoet was able to react and adapt to a changing operational environment.

“We work a lot with HSM Offshore. They always involve us at the beginning of projects, so we can help them with smart solutions for assembly,” adds Segeren.

“Through strong cooperation and our early involvement, we were able to help them come up with a smart approach for the assembly of the jacket and reduce the lead time for construction”.

Mammoet | www.mammoet.com

.jpg?r=2973)