Future-Proofing Wind Energy: How advanced monitoring strengthens grid resilience

As wind energy continues to expand its role in the global energy transition, ensuring the reliability of power transmission from offshore and onshore wind farms is critical. Power cables are the backbone of this infrastructure, transporting electricity from turbines to substations, and eventually to consumers. But what happens when a fault occurs? How do operators mitigate external threats like anchor strikes, seabed erosion, or excavation activities near buried cables? And how can they optimize cable performance in real time?

Addressing these challenges calls for advanced monitoring solutions such as real-time thermal rating (RTTR), cable fault location, and third-party intrusion (TPI) detection. These technologies play a vital role in protecting wind energy assets and ensuring uninterrupted power transmission.

The need for cable monitoring in wind energy

High-voltage alternating current (HVAC) and high-voltage direct current (HVDC) cables are essential for transmitting electricity from offshore wind farms to the mainland and distributing power within onshore wind networks. However, these cables are exposed to numerous risks: Subsea power cables are vulnerable to anchor strikes, fishing activity, tidal movements, and seabed erosion, which can lead to exposure and damage. Underground cables that connect onshore wind farms face threats from excavation, construction, and environmental factors such as soil erosion or flooding. Also, wind energy’s variable nature demands real-time insights into cable conditions to maximize efficiency and grid stability. Early detection of faults, thermal anomalies, or external threats is essential to prevent costly repairs and unplanned outages that could disrupt wind energy production.

Thermal monitoring: The key to maximizing wind power transmission

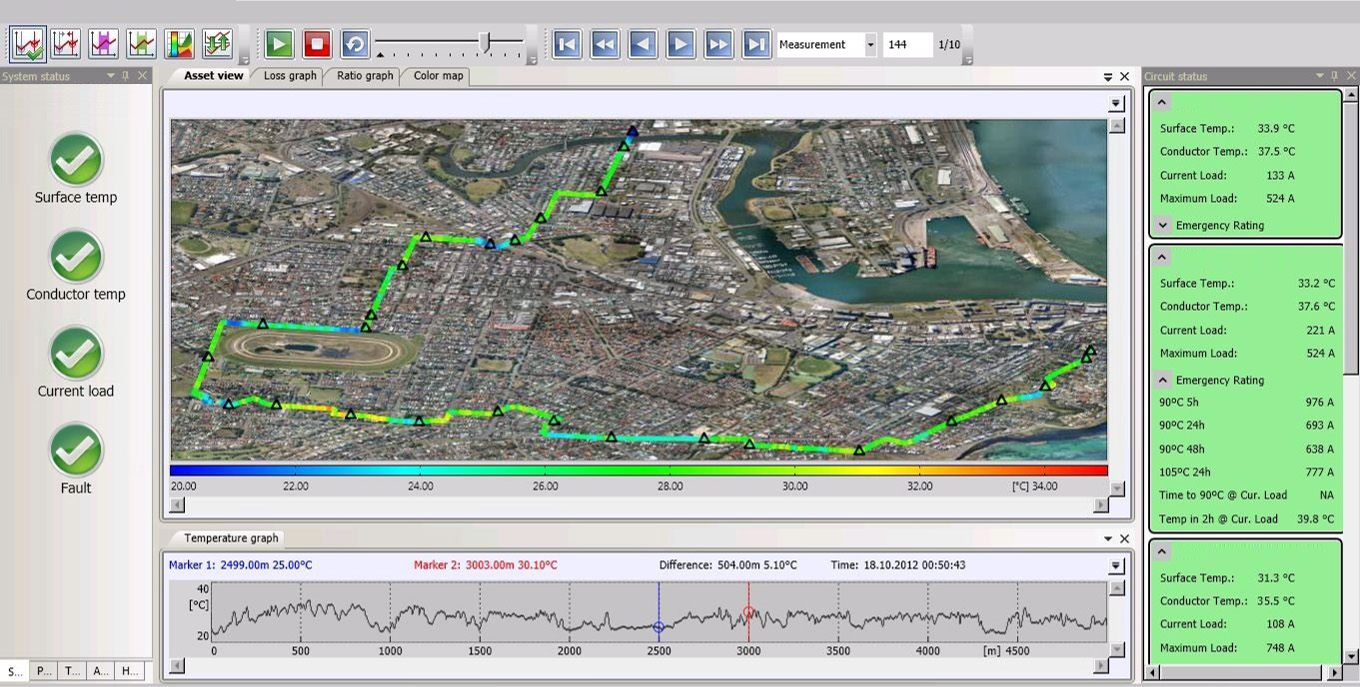

One of the most effective ways to ensure the safe and efficient operation of wind power transmission is thermal condition monitoring. By continuously tracking temperature variations along power cables, operators can detect overheating, optimize load management, and prevent failures.

Real-time thermal rating (RTTR) goes a step further, dynamically assessing a cable’s thermal capacity based on environmental and operational conditions. This allows wind farm operators to maximize transmission capacity without exceeding safe temperature limits, extend cable lifespan by preventing thermal stress, and improve grid stability by adapting to fluctuating energy output.

When combined with advanced fault detection and external threat monitoring, these technologies provide a comprehensive approach to wind power cable management.

Fiber-optic monitoring: A smart solution for wind farms

Fiber optic-based monitoring is revolutionizing wind energy infrastructure by offering a passive, non-invasive way to track cable health in real time. Technologies such as Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) transform fiber optic cables into continuous sensors, delivering a complete view of power cable conditions.

DTS continuously monitors temperature along the entire length of the cable, enabling RTTR and early fault detection, while DAS detects acoustic signals related to third-party intrusions, such as anchor drops, drilling, or excavation near buried cables.

With these insights, wind farm operators can act before damage occurs, reducing downtime and enhancing grid reliability.

Real-world impact: Safeguarding offshore wind infrastructure

A compelling example of advanced monitoring in offshore wind energy can be found in Denmark, where a fiber optic-based sensing system was deployed to safeguard the critical power transmission infrastructure of the Horns Rev 3 offshore wind farm. Located off the west coast, this 400 MW wind farm required a monitoring solution to ensure uninterrupted power transmission and rapid fault detection across both subsea and underground cables.

To enhance reliability, Distributed Acoustic Sensing (DAS) detects acoustic signals that may indicate third-party interference, such as anchor drops near subsea cables. At the same time, Distributed Temperature Sensing (DTS) provides real-time thermal monitoring, ensuring that cables remain within safe operating limits, and enabling operators to optimize transmission capacity dynamically.

An integrated visualization platform allows multiple operators to access real-time temperature and acoustic data, offering a clear overview of cable health. Since installation, the system has performed reliably, supporting long-term grid stability and proactive maintenance strategies.

A smarter future for wind energy

As wind energy capacity grows, so does the need for smarter, data-driven asset management. Advanced monitoring solutions empower wind farm operators to:

- Enhance reliability: Detect faults and external threats before they escalate

- Optimize performance: Maximize cable capacity and efficiency

- Support sustainability: Reduce energy losses and improve grid stability

In a world where wind power is key to a cleaner future, proactive monitoring isn’t just an option — it’s a necessity. By leveraging fiber optic-based solutions, wind energy operators can ensure resilient, high-performance transmission systems for decades to come.

Dr. Henrik Hoff is Business Director, and Earl Curtis is Director of Sales, Power & Utility at AP Sensing, which offers distributed fiber optic sensing technologies to industries around the globe.

AP Sensing | www.apsensing.com

Author: Dr. Henrik Hoff and Earl Curtis

Volume: 2025 March/April