How Wind is Guiding the Maritime Industry

Like long-lost siblings, the wind energy and maritime shipping industries share distinct DNA in their approach to wind measurement technologies. While wind turbines convert wind energy into electricity, the maritime sector harnesses the same natural force through wind-assisted ship propulsion, or WASP.

A recent industry survey reveals striking parallels in how wind-assisted ship propulsion (WASP) operators increasingly adopt remote sensing solutions and wind measurement techniques already familiar to wind farm operators. Following up on 2022 data, the survey shows maritime operators following a trajectory similar to wind farm developers — moving from simple anemometers to integrated sensor networks and wind lidar systems.

Both industries rely on the same success factor: precision in understanding wind behavior. Perhaps the emergence of wind lidar and other sensor technologies can transform this shared challenge into a technological advantage as both sectors help shape a greener future.

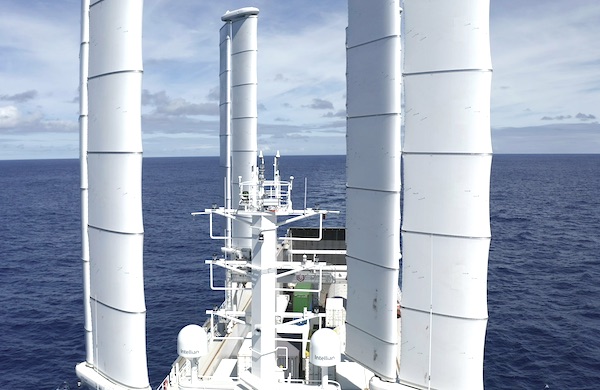

MARIN conducted performance tests using Vaisala WindCube Nacelle horizontal profiling wind lidar on Canopée.

Maritime wind technology adoption accelerates

Like meteorological masts, mechanical anemometers often struggle to keep up with evolutions in the maritime environment, where ship structures, harsh environmental factors, turbulence, and local “masking” effects can distort measurements, even leading to wind speed inconsistencies as vast as exceeding 50 percent.

Survey responses from WASP system manufacturers (including wings, soft sails, rotors, rigid sails, and suction sails) and shipping companies show precise wind data is a massive priority. A whopping 75 percent of respondents now rate local wind measurements as “very important,” where 2022 saw only 20 percent rating local wind measurements as very important.

System optimization seemingly drives this shift, with 87.5 percent of respondents using wind measurements to directly adjust their WASP systems. Safety enhancement and operational state control emerged as other benefits: two applications echoing evolving wind farm practices on and offshore.

As wind measurement priorities shift, equally significant changes arise in the technologies deployed across vessels.

The wind measurement technology evolution

Maritime decision-makers increasingly favor ultrasonic anemometers over their mechanical counterparts. More than 68 percent of maritime respondents utilize ultrasonic anemometer technology due to advantages familiar to wind farm operators: no moving parts to maintain, quick turbulence measurement sampling rates, and durability in challenging environments.

Sensor placement strategies reflect a progressive understanding of wind flow dynamics. Industrywide, installations favor mast positioning (68.8 percent), bridge-top placements (56.3 percent), and bow-mounted sensors (50 percent). The maritime shipping sector’s newfound multipoint sensor approach parallels wind farm practices of measuring wind resources at various heights and locations across wind farm sites, whether to optimize turbine placement or validate power performance models.

While traditional anemometry provides the foundation for maritime wind measurement, the industry’s most dramatic technological leap involves remote sensing capabilities.

Ultrasonic anemometers combined with the wind lidar improve the accuracy of wind data for WASP system optimization

Remote sensing transforms maritime operations

Undoubtedly the survey’s most significant finding is this: the interest in wind lidar is greater than ever. Zero respondents indicated lidar interest in 2022, yet almost 70 percent now view lidar based remote wind measurement as crucial — a transition underscoring wind energy’s growing embrace of lidar for wind resource assessment and turbine control.

Maritime applications of lidar technology also offer advantages similar to wind power generation, particularly in providing upstream measurements for predictive system adjustments. Key benefits identified by survey respondents include system optimization (75 percent), enhanced safety capabilities (56.3 percent), and route optimization (25 percent).

Despite enthusiasm for advanced measurement technologies, implementation hurdles persist.

Technical challenges bridge maritime and energy sectors

No matter how far technology advances, implementation remains a vexing challenge. Stakeholders praise the accuracy and environmental robustness of current sensor solutions. However, nearly 45 percent still seek enhanced measurement precision, a concern shared by wind farm operators pushing for greater efficiency.

The survey identifies several technical challenges familiar to wind energy professionals:

- Complex wind field measurement — around ship’s structures at sea and in all types of complex terrain for wind farm development

- Flow interference and turbulence effects

- Integrating multiple data sources for a comprehensive understanding of the wind’s behavior

- Communication interface reliability

- Data quality continuity in harsh and/or remote environments

These shared technical challenges have pushed both industries toward similar solutions, particularly in their approach to sensor networks.

Vaisala WindCube Nacelle horizontal profiling wind lidar installed on SC Connector RoRo vessel beside the Norsepower Rotor Sail

Multisensor solution integration trends

Players across maritime industry segments increasingly favor more complete sensor networks, with 62.6 percent of 2024 respondents preferring three or more sensors per vessel, up from a predominantly dual-sensor inclination in 2022. Yet again, this trend mirrors wind farm operations, where multiple measurement points provide redundancy and a more complete understanding of wind resource behavior.

The maritime industry’s rapid evolution in measurement technology adoption offers valuable insights for wind energy professionals facing similar optimization challenges.

Top lessons for clean energy development

What can we learn? The survey results reveal how another industry tackles familiar challenges in wind resource measurement and system optimization. Key takeaways include:

- The growing importance of integrated measurement systems that combine local and remote sensing data rather than relying on limited or single-point data.

- The value of multipoint measurements in understanding complex wind interactions.

- Predictive capabilities and forecast data critically help optimize wind-based systems.

These lessons from maritime adoption of wind measurement technologies point to broader opportunities for cross-industry innovation.

Cross-industry learning powers progress

Two industries, one mission: Harness the wind more effectively through advanced measurement technology. Though it remains unclear whether algorithms used in wind energy to optimize turbine performance can do the same for route planning and WASP system adjustments in maritime shipping, the possibility exhibits how industries can innovate collaboratively.

Leveraging shared challenges — accurate wind measurement, system optimization and environmental adaptation — can help both sectors move forward.

The survey results reveal more than just changing preferences; they highlight the potential benefits of continuous innovation for both sectors, particularly in data integration and predictive analytics. Collaborative data efforts could support better decision-making, combining datasets from both industries for broader insights into wind patterns, environmental impact, and operational efficiency.

The convergence of maritime shipping and wind energy generation technologies — and the resulting opportunities — highlight the interconnected nature of the renewable energy ecosystem, where innovation in one area often drives progress throughout others.

Mikko Nikkanen leads strategy and development for Vaisala’s Maritime segment. He has established Vaisala’s maritime focus in modern weather awareness solutions, bringing 20 years of global sales and business development experience to build innovative solutions with various partner ecosystems.

Mikko Nikkanen leads strategy and development for Vaisala’s Maritime segment. He has established Vaisala’s maritime focus in modern weather awareness solutions, bringing 20 years of global sales and business development experience to build innovative solutions with various partner ecosystems.

Vaisala | www.vaisala.com

Author: Mikko Nikkanen

Volume: 2025 March/April