Lidar is Changing the Game for Wind Measurements

Wind power is exploding thanks to the rising need for renewable energy, favorable government policies, and increased investments in research and development. Despite this surge in popularity, however, the wind industry also faces several challenges.

Traditional wind measurement methods, such as meteorological masts (met masts), need help keeping up with growing wind turbine sizes, as well as the development of more offshore wind farms. Inherent risks of using met masts include needing maintenance or inspection personnel to climb them (putting people at risk of falls), and the susceptibility of the structures to lightning strikes or collapse.

As the wind energy industry booms, and turbines continue growing taller than met masts can measure, the need for accurate and safe wind measurement solutions is greater than ever. Fortunately, lidar technology is rapidly replacing met masts — with some of the biggest names in the industry utilizing the technology across the wind energy project life cycle.

Standalone Lidar Campaign Improves Operational Efficiency and Worker Safety

Standalone Lidar Campaign Improves Operational Efficiency and Worker Safety

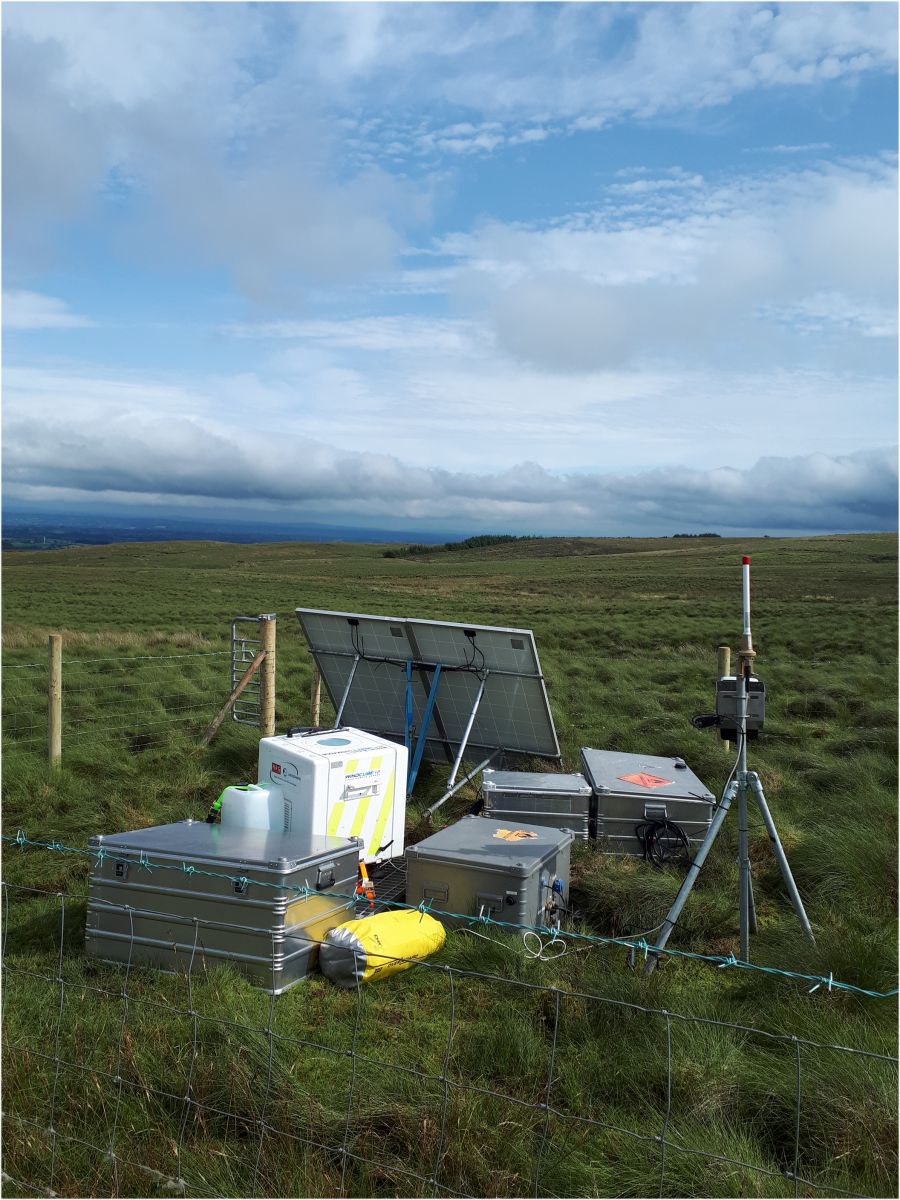

By turning to standalone lidar as a safer and more accurate alternative, one company chose to implement lidar at the Corlacky Hill project in Northern Ireland. This decision helped improve employee safety and reduce operational costs by 40 percent, increasing overall efficiency.

Utilizing vertical profiling, standalone lidar, wind measurements were gathered for 12 months. The data was used to evaluate the wind farm's independent energy production. This data was also shared with wind turbine original equipment manufacturers to determine the suitability of turbines. Advanced lidar technology allows for optimal wind farm layout, maximizing energy yield while ensuring compliance with industry standards.

With numerous lidar systems deployed worldwide in both onshore and offshore settings, this modern solution continues revolutionizing how WRAs are conducted in the wind energy sector.

Dual scanning lidar in wind farm design

Acknowledging the need for accurate wind measurements in offshore wind farm development, another company engaged two standalone lidar devices, which were placed on offshore platforms. This enabled accurate mapping of wind resources for one campaign with a typical range of up to 10 kilometers, from several positions simultaneously.

Lidar’s enhanced monitoring capacity leads to more informed decision-making during wind farm development. The innovative dual-scanning lidar configuration collects data more consistently and reliably than met masts, which reduces the likelihood of errors or inaccuracies over a larger area in less time. Utilizing dual scanning lidar during offshore wind farm development yields superior design maps and reduced measurement uncertainties, compared to using a single met mast in a campaign.

When comparing one met mast to a dual scanning lidar setup, a 6 percent error was discovered in the single met mast case. Using dual scanning lidar means that companies can ultimately “install” more virtual met masts, which helps to reduce measurement uncertainty during offshore WRA, and to create a competitive bid in a wind farm development auction.

Vaisala dual scanning lidars, courtesy of Green Power Investment

Nacelle-mounted lidar for PPT

In light of the recent release of the IEC 61400-50-3 standard, embracing the use of lidar for wind turbine performance testing means working with companies, customers, and third-party engineers to test the accuracy, reliability, and robustness of nacelle lidar.

As evidenced by the recent IEC standard, the industry's confidence in nacelle-mounted lidars has grown significantly, mainly due to its accuracy in measuring hub-height wind speeds. Throughout the field research, the nacelle-mounted lidar delivers accurate wind speed and direction measurements to research teams, enabling decision-makers to optimize the power performance of the turbine, and increase energy output.

With growing trust in this advanced technology, lidar campaigns are quickly becoming more popular than met masts for power performance testing and wind farm development.

Increasing lidar acceptance and usage

Thanks to incredible advancements in lidar technology, the future of wind energy is brighter than ever, with the potential for even more improvements and innovations. Researchers are continually exploring ways to enhance the technology's capabilities, such as increasing its range, improving its accuracy, and integrating it with other systems for seamless data analysis. Lidar will continue to advance and revolutionize wind measurement campaigns, bolstering the industry's capacity to meet the soaring demand for clean energy worldwide.

Adopting lidar technology has not only improved the safety and accuracy of wind measurements, but also played a crucial role in the overall growth of the wind energy industry. Many developers recognize that lidar technology addresses the challenges faced by the wind energy industry, and it offers innovative solutions to address the issues arising in this rapidly advancing market.

With lidar becoming the modern standard for wind measurement campaigns worldwide, developers and investors can now access precise on-site wind data, reducing project uncertainty, and increasing value at every stage of a wind farm project.

.jpg) Elvira Aliverdieva is Product & Offering Specialist at Vaisala | Renewable Energy, where she participates in the evolution of the company’s onshore and offshore wind product strategy.

Elvira Aliverdieva is Product & Offering Specialist at Vaisala | Renewable Energy, where she participates in the evolution of the company’s onshore and offshore wind product strategy.

Vaisala | www.windcubelidar.com

Author: Elvira Aliverdieva

Volume: 2023 July/August