One Platform to Power Them All: Achieving excellence across mixed wind fleets with purpose-built software

As electrification expands around the globe, utilities are experiencing an increasing need to incorporate more green energy solutions into their generation portfolios. Wind assets are a key element of this strategy, not only because they are an efficient way to produce sustainable energy, but also because they have been around for decades. The technology is stable and reliable, making wind a perfect addition to a green energy portfolio.

While some companies are building out new farms and purchasing new turbines, it’s often an expensive and complicated process. Tightening regulations around new turbines make it difficult — and sometimes impossible — to perform new installations in certain areas. Fortunately, wind turbines are not only well understood, but also readily available, with existing farms dotting the landscape across the globe. This makes them a perfect target for acquisition as a traditional utility expands its green energy portfolio, with most companies running a combination of new equipment and legacy turbines across their fleets.

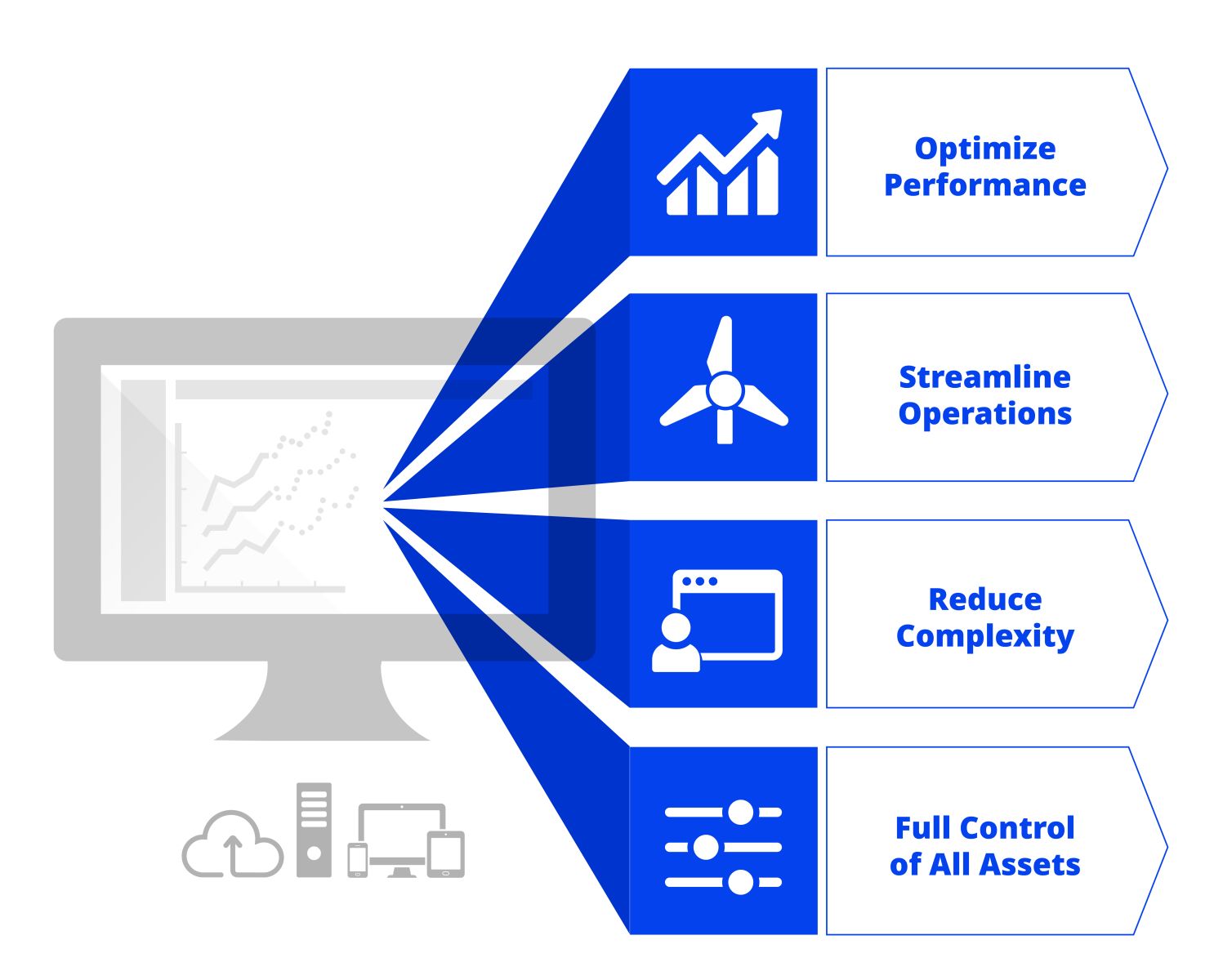

However, the process of combining new and legacy assets across a local, regional, or even global network, and then monitoring and managing those assets remotely, is often a complex endeavor. To achieve peak operational excellence, companies need a way to bring everything together for seamless operation. This means finding ways to reduce complexity, even when a fleet is made up of many different turbines of different ages across a wide spectrum of manufacturers. The most effective utilities are finding that the best way to reduce complexity is to build a common platform using a fit-for-purpose green energy software portfolio, providing supervisory control and data acquisition (SCADA), asset performance management (APM), and maintenance and diagnostics (M&D) solutions (Figure 1).

Figure 1: As power generation companies expand their wind portfolios with both new and legacy turbines, they need a way to bring everything together for seamless operation, using a fit-for-purpose software solution.

The pains of power production

The biggest challenge that utilities face when managing their wind assets is when they acquire new and legacy turbines, and find themselves owning a wide array of OEM control systems that do not integrate. When buying brand new turbines, the company will likely purchase both what is available, and what best fits the topography where it will be installed. Each time, the best solution may be from a different manufacturer. Conversely, when acquiring existing turbines, companies receive the equipment that is in place; those assets may be from different manufacturers than what the utility already owns, or even different within the same park. Typically, each OEM SCADA or APM solution will only interface with the manufacturer’s own turbines.

This wide array of control solutions creates a lot of complexity. First and foremost, operators will need to understand how to navigate a variety of interfaces and spend time moving between them to operate, monitor, and maintain all the turbines. In addition, the siloed data in each turbine control system makes it extremely difficult to compare performance and asset health. To do so, teams need to extract data manually — assuming the right data points are available — and perform complex manual calculations to track and trend performance. Finally, teams managing a variety of different control systems will also struggle to bring all their data into a single remote operations center, which is becoming more common as fleets span wider global areas. With limited access to data from a wide variety of solutions, bringing data together quickly becomes a complex endeavor.

Homebrew solutions often miss the mark

Often, to navigate the complexity of a wide variety of turbine control solutions, companies purchase a third-party business intelligence (BI) tool to collate data from different manufacturers via an open protocol. Such a solution can bring some data into a centralized location, but it presents a number of challenges. Configuration of such tools is often complex, requiring significant time, knowledge, and resources up front to configure, as well as additional time, knowledge, and resources to maintain over its lifecycle.

In addition, custom BI solutions typically have very limited access to turbine control and reliability data. Often, due to OEM limitations, BI solutions using an open protocol to collect data have access to fewer than 100 data points from any given turbine, far less than is necessary to unlock full control and monitoring from a remote location. This limits the team’s ability to keep turbines in high availability and operate them in the most efficient way.

Fit for purpose functionality

The most effective operators are navigating the complexity of their operations with a fit-for-purpose, OEM-agnostic green energy software portfolio encompassing SCADA, APM, and M&D functionality. The most effective green energy portfolios use custom protocols, built to interface directly with nearly every wind turbine on the market to collect tens of thousands of data points from each asset. Armed with all the necessary data, teams can optimize their entire process for maintenance and operation. Operators and technicians can see which parameters have been changed over time, and how the changes contribute directly to asset availability (Figure 2).

Figure 2: A unified green energy platform offers the consistency and scalability needed to optimize performance, streamline operations, and maximize returns across the entire lifecycle.

Moreover, all those data points are fed directly into a central system designed with custom views, dashboards, and key performance indicators out of the box, and users can further refine those capabilities by adding their own custom tools. Armed with real-time data, the system can alert operators automatically when trends are moving in the wrong direction, and provide actionable recommendations for how to react via decision support grounded in decades of wind industry expertise.

A roadmap to operational excellence

Whether a company is purchasing new turbines or integrating legacy assets as part of an acquisition, simultaneously implementing a fit-for-purpose green energy software portfolio is a strong investment choice. In legacy assets, end-of-life OEM control systems likely offer limited capabilities and no patches, support, or new features — all issues that can be quickly solved with the industry’s best green energy portfolios. Moreover, even for new asset purchases, companies will have limited capabilities with OEM control solutions. Most would be better served opting instead for a comprehensive software portfolio, giving them full control of their most critical assets and setting them on a faster path to operational excellence across the lifecycle of their assets.

Thomas Andersen is Vice President of Renewable Technologies for Emerson. He has more than 30 years of renewables control and optimization experience, with a keen focus on wind generation. He began his career as an electrical technician with Mita-Teknik, a company known for its work in wind generation control. In 2009, Andersen was promoted to Mita-Teknik’s chief technology officer where he drove the development of state-of-the-art solutions used by wind turbine manufacturers, OEMs, and owners and operators all over the world.

Thomas Andersen is Vice President of Renewable Technologies for Emerson. He has more than 30 years of renewables control and optimization experience, with a keen focus on wind generation. He began his career as an electrical technician with Mita-Teknik, a company known for its work in wind generation control. In 2009, Andersen was promoted to Mita-Teknik’s chief technology officer where he drove the development of state-of-the-art solutions used by wind turbine manufacturers, OEMs, and owners and operators all over the world.

Emerson | www.emerson.com

Author: Thomas Andersen

Volume: 2025 January/February