Prevent Wind Turbine Gearbox Failures: Expert insights from a forensic engineer

Wind turbines play a central role in the growing renewable energy sector. Behind their towering blades and energy production, however, lies a complex mechanical system prone to failure.

As a forensic engineer, I have dedicated much of my career to studying mechanical systems and equipment failures, ranging from wind turbines to large engines. Over the years, I have learned that the key to preventing significant breakdowns often lies in understanding how these systems function smoothly and identifying the factors that lead to their failure.

Let’s dive into the common reasons for wind turbine gearbox failure, how forensic analysis helps identify the root cause, and why early intervention is essential.

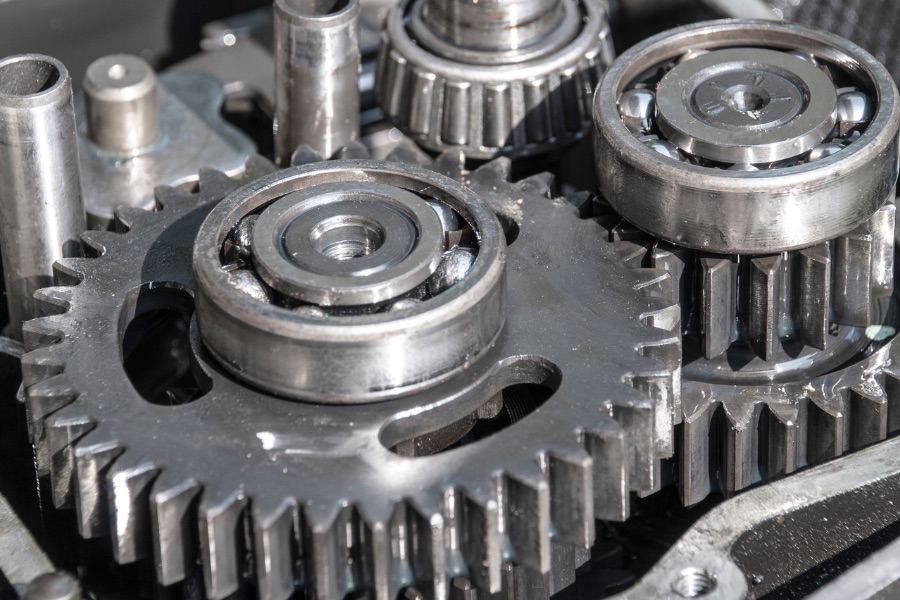

image courtesy of Canva

What is a wind turbine gearbox?

The gearbox is one of the most crucial components of a wind turbine. It converts the slow rotation of the blades into the high-speed movement necessary for electricity generation.

Common causes of wind turbine gearbox failures

Wind turbine gearboxes are susceptible to failure due to stress, wear, and other factors. Having designed high-speed and planetary gearboxes for various industries, I have witnessed firsthand how these factors can lead to issues. Here are some of the most common causes:

1. Improper maintenance: Regular lubrication and monitoring are critical to avoiding premature wear. Lubricants and essential components can degrade without proper maintenance, leading to increased friction and quickly progressing to failure.

2. Component defects: Gearboxes must be manufactured with precision using durable materials. Substandard materials or components can develop cracks or fractures, or degrade under stress, ultimately failing over time.

3. External damage: Wind turbines operate in harsh environments. Severe weather and other external factors, such as debris or lightning strikes, can overload or damage gearboxes. If these issues are left unchecked, they can lead to catastrophic breakdowns.

One of the earliest signs of potential gearbox failure is excessive vibration, which the turbine's condition monitoring system can detect. This system identifies damage to the bearings, gears, and other essential gearbox components. If detected early, these issues can often be addressed by replacing individual parts, which reduces downtime and repair costs. However, if not addressed promptly, minor problems can escalate into costly repairs and significant downtime, making timely responses to detected issues one of the biggest concerns in wind turbine maintenance.

image courtesy of Canva

How forensic engineers investigate wind turbine gearbox failures

When a wind turbine gearbox failure occurs, a systematic forensic investigation is vital for determining the root cause. A structured approach ensures thorough analysis and accurate reporting:

1. Initial site visit: We gather data, examine the site, and consult with technicians and others who work directly with the turbine to gain insight into what may have gone wrong.

2. Visual examination: We inspect the damaged components for signs of wear, defects, or external damage.

3. Detailed disassembly and root cause analysis: In collaboration with a third party, we conduct a methodical disassembly, examining internal components to identify the root causes of the observed failures.

4. Report preparation: After a thorough investigation, we compile our findings into a comprehensive report that clearly explains the cause of failure. This equips insurers and operators with the information needed to make informed decisions about coverage and repairs.

Early intervention by forensic engineers is crucial for a successful investigation. The sooner we are involved, the more accurate data we can gather, leading to a better understanding of what went wrong. This is especially important in wind turbine gearbox failures, where minimizing downtime and financial loss is critical.

image courtesy of Canva

Lessons from other mechanical failures

While wind turbine gearbox failures are a significant focus in the renewable energy sector, they are not the only large mechanical systems prone to failure. I have also spent years analyzing failures in large engines, such as those found in generator sets, compressors, and pumps in fracking and energy installations, among other sites, where equipment damage can amount to millions of dollars.

Although they differ from gearboxes in many respects, engines often experience breakdowns due to similar underlying mechanisms as wind turbine gearboxes. These include mechanical wear, lubrication issues, component defects, and problems arising from improper assembly.

My forensic travels have taken me across North America and overseas to assist in root-cause analyses of significant engine failures. The level of detail involved in these investigations is often extensive, covering everything from meticulous inspection of engine components to thorough reviews of maintenance records and operational data. Being well acquainted with the complexities of large engines in power generation, oil and gas, and other industries often provides insights into prevention and mitigation strategies.

When the worst happens, you need a forensic engineer ready to assist with investigations, and help operators make informed decisions to minimize downtime and financial loss. Whether it’s a wind turbine gearbox, a large engine, or a solar installation, understanding the root cause of a failure is the first step to preventing it from happening again.

Chris S Spies, P.E., is a consulting engineer at Engineering Design & Testing Corporation (EDT), specializing in the forensic analysis of mechanical, vehicle, and industrial systems and equipment failures. With a strong background in engine assembly and design of compressors, gear drives, and complex mechanical systems, Chris provides expert insights into the causes of equipment failures to help clients make informed decisions. Engineers at EDT possess a comprehensive understanding of a wide range of energy technologies, demonstrating their competence and ability to handle complex issues in the renewable energy sector.

Engineering Design & Testing Corporation | www.edtengineers.com

Author: Chris S Spies, P.E.

Volume: 2025 March/April