Taking Autonomous Inspection to New Heights

The multibillion-dollar tax credit from the Inflation Reduction Act (IRA) is set to unlock a new level of growth in wind power. Some energy consultants go so far as to estimate installed capacity to double by 2030.

That begs the question - do we have what it takes to handle the challenges that accompany this kind of growth?

The short answer is yes, but with an asterisk.

Here’s what we mean.

Turbine inspections are limited, in large part, due to cost and logistical constraints. The need for an O&M solution that gives way to regular inspections will only grow stronger as turbine installations kick into a higher gear. Fortunately, there’s a new piece of technology turning out to be a tried-and-true way of letting operators conduct checkups on the fly.

Enter miniaturization.

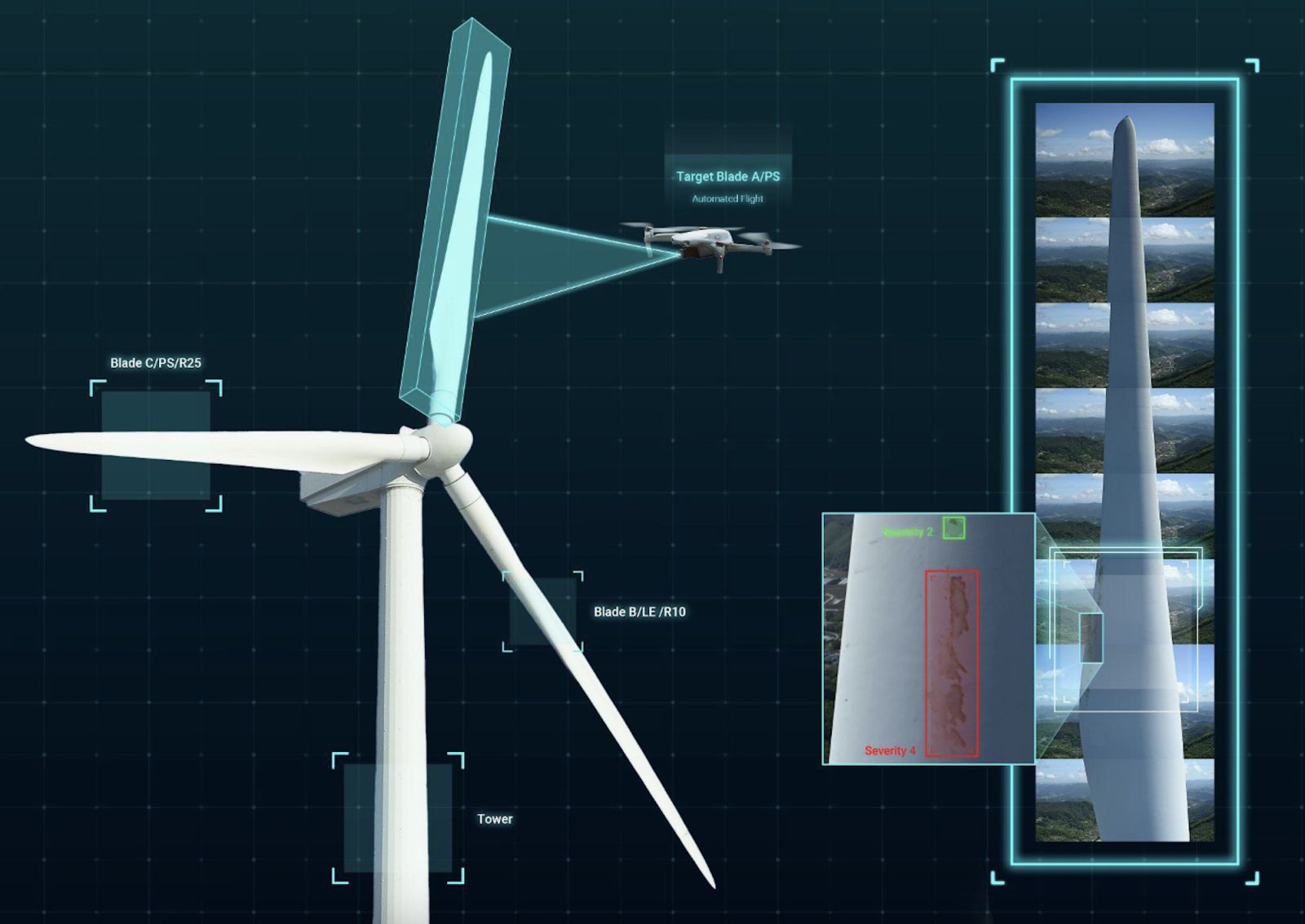

By turning off-the-shelf commercial products into autonomous drones with the power of AI, miniaturization is paving the path to a future where standalone checkups are thrown into the mix alongside regular inspections.

Humble Beginnings

Before diving straight in, let’s take a step back and look at how we even got to the point where Unmanned Autonomous Vehicles (UAVs) became a coveted piece of equipment for streamlining O&M workflows.

As recently as a decade ago, drones had yet to make their way into the energy infrastructure domain. Today, a largenumber of wind farms rely on UAVs to keep the turbines spinning, and the question of tapping into drone technology has evolved from “if” to “when.”

Given that drone-based inspection reduces lost revenue from prolonged downtime by 90 percent — and spares technicians from throwing themselves in a spot where their lives are hanging by a rope — the fast rise of drone inspection might look like a preordained outcome.

At first, no one saw drone tech as the future. The idea of using UAVs for O&M purposes seemed rather far-fetched. The typical climate in which turbines are installed seemed too harsh. Worse, much of the success hinged on the dexterity of the pilots, whose skill level dictated the quality of aerial images.

The strides made by drone inspection didn’t materialize out of thin air. Only after years of grueling trial and error are we seeing highly autonomous AI-powered drones handle the work with minimal human supervision.

How It All Came About

Miniaturization is no different. This new level of technology is set to spearhead the next generation of O&M. It’s a culmination of rigorous R&D led by forward-thinking service providers, all of whom have rallied around a common cause of clearing the roadblocks that hold wind farms back from conducting inspections more than once or twice a year.

The easiest way to think about these roadblocks is in three broad categories:

- Shortage of skilled pilots. A shallow talent pool makes it challenging to carry out inspections in due course.

- Cost. The number of resources that go into procuring the equipment and enlisting outside help tends to outweigh ground-based inspections.

- Logistical constraints. Strict shipping standards, burdensome pre-approval paperwork, unfavorable regulations, and the like, may lead to further delays.

All three factors point to one thing – industrial-grade UAVs. Had it been any other professional camera drone, none of these would’ve presented an issue.

Take photographers and YouTubers, for example. They use drones for their content all the time. What we don’t see are bottlenecks of any sort hindering their creative process. Many of them simply go on Amazon to snap up a drone, and maybe some extra batteries, skim through the manual, then start shooting.

What if, instead of focusing on manufacturing heavy-duty drones with cheaper, lighter materials, our industry worked out a solution that empowers these off-the shelf drones to do the work?

Inspecting Outside the Box

It didn’t take long for miniaturization to take off.

Ad hoc inspections became an everyday thing. Whenever site managers spotted a need for a checkup, they did so on the day of with an off-the-shelf product they bought from the nearest hardware store.

This alone wouldn’t have been as impressive if the site managers had prior experience flying drones. But none of them did. All it took to perform the inspections was a day of training to nail down the ins and outs of the software.

The best part? None of the day-old pilots seemed fazed by the chances of a potential crash. Knowing that the biggest liability looming over their heads is a tiny nick, everyone performed at their best from the get-go, without letting nerves get in the way.

The availability of ready-made drones, their ease of use, and the minimized risk of property damage all came together to let wind farm technicians bypass the operational hurdles that had long been in their way of conducting routine inspections.

The Future of Autonomous Drone Inspection

The benefits that come with the ability to check up on the assets at will are pretty much self-explanatory. But here’s a simple way to look at it.

Turbines wear and tear with everyday use. While full-fledged inspections are valuable in their own right, looking over assets once or twice a year is nowhere sufficient to stay up to speed on the state of the turbines.

By internalizing miniaturization into O&M workflows, you can prevent minor defects from snowballing into bigger problems, while setting the stage for a future where predictive maintenance helps keep turbines in tip-top shape all year round.

Jay Choi is the co-founder and CEO of Nearthlab, a provider of autonomous drone solutions for blade inspections. Jay brought together his prowess in aerospace engineering, and years of experience as a plant engineer, to redefine the industrial inspection landscape through the use of UAVs. His efforts culminated under the auspices of Nearthlab, which has grown to be a trusted service provider to wind farms around the world since its launch in 2015.

Nearthlab | nearthlab.com

Author: Jay Choi

Volume: 2023 January/February

.jpg?r=1123)